Compiled by F. R. Chowdhury

Image Credit: ClassNK

Image Credit: ClassNK

1. Certificate of Survey:

– This is done on behalf of the Flag State prior to the registration of the vessel to establish the authenticity/ identity of the vessel and to ensure that particulars given/ obtained are correct.

2. Certificate of Registry:

– This is the identity document of the ship. Issued by the Flag State Administration. It will contain the name of the ship, name and address of the Owners/ Bare-boat charterers, LR-FP Identity Number, Port of registry, dimensions and tonnage, IMO number, Call Sign and the Nine-digit Maritime Mobile Service Identity (MMSI), name of builder and year of build, type/class of ship, features like number of decks, bulkheads, masts, propellers and brief details of machinery and power. In some countries it may be necessary to record the name of the Chief Executive or other responsible person in the company who is to be contacted in an emergency. (The UN Convention on Registration of Ships 1986 (not yet in force) and UNCLOS-82 provide general guidance on this subject.)

3. Carving and Marking Note:

– Issued by the Flag State. This is signed and returned by the surveyor when he is satisfied that the vessel is marked accordingly (Guidance: Regulation XI-1/ 3 of SOLAS74).

4. International Tonnage Certificate:

– Issued under International Tonnage Convention 1969 (Article 7). Port dues, light dues, berth charges, pilotage etc, are normally charged on the basis of Gross Tonnage (GT) of the Ship.

– Issued under International Tonnage Convention 1969 (Article 7). Port dues, light dues, berth charges, pilotage etc, are normally charged on the basis of Gross Tonnage (GT) of the Ship.

– Ships passing through Suez and Panama are charged on the basis of respective Canal Tonnage Certificate. They have separate rules for measurement and the Classification Societies can provide with these certificates after necessary measurement and calculation.

Dead-weight of a ship, which is the difference between the loaded and light displacements, should not be confused with tonnage.

5. Anchor & Chain/ Cable Register :

– Ships shall carry on board certificate relating to

– Ships shall carry on board certificate relating to test of anchor and attached chain.

6. Plan Approval:

– For new building it is essential that plans are approved in advance so that post-building alterations can be avoided. For existing ships (changing flag), it is necessary to check and ensure that the design, features, material and construction of the vessel have not been altered or changed since the original approval of the plan and that the ship meets the construction requirements (SOLAS, MARPOL, LL) as applicable to an existing ship for the relevant period. The important elements are sub-division, structural fire protection and escape route.

It is now a requirement to mark ship’s plans and manuals with IMO number and to have “as built” plans available on the ship and the office during the life of the vessel.

SOLAS74 II-1 Part A-1 Regulation 3-1 requires ships to be designed, constructed and maintained in compliance with structural, mechanical and electrical requirements of a recognized classification society.

7. International Load Line Certificate:

– Issued under International Load Line Convention 1966 (as amended by the Protocol of 1988) and applies to ships of 24 meters or more in length.

– Issued under International Load Line Convention 1966 (as amended by the Protocol of 1988) and applies to ships of 24 meters or more in length. Basically it is a measure to prevent over-loading of ships which otherwise endangers lives of the seafarers. There are six essential ingredients – 1) Strength of hull 2) Watertight integrity 3) Stability 4) Mandatory freeboard 5) Freeing ports and 6) Crew protection.

Certificates are issued for five years subject to annual and intermediate Inspection

A freeboard report will be attached. Record of particulars relating to Conditions of Assignment shall be issued. There shall be also an Intact Stability booklet.

(Damage Stability is covered by SOLAS).

8. Passenger Ship Safety Certificate

– Issued in compliance with SOLAS74 and Protocol 88 Reg. I/12. It combines the relevant requirements of SOLAS chapters II-1, II-2, III, IV and V and any other relevant requirements of the present regulations The certificate is valid for one year.

– Issued in compliance with SOLAS74 and Protocol 88 Reg. I/12. It combines the relevant requirements of SOLAS chapters II-1, II-2, III, IV and V and any other relevant requirements of the present regulations The certificate is valid for one year.

A Record of equipment for Passenger Ship Safety Certificate shall be attached.

9. Cargo Ship Safety Construction Certificate:

– Issued under SOLAS74 to ships of 500gt and over which meet the criteria outlined in Chapter II (other than those relating to fire safety systems and appliances and fire control plans) such as Structural Fire Protection, Double bottom,

– Issued under SOLAS74 to ships of 500gt and over which meet the criteria outlined in Chapter II (other than those relating to fire safety systems and appliances and fire control plans) such as Structural Fire Protection, Double bottom, Sub-division and Stability, W/T doors, Means of going astern, Steering, Pumping, Emergency lighting, light and Sound Signals etc. The Certificate is of 5 years duration with requirement for intermediate and annual endorsements. Cargo ships are required to be dry-docked twice in any five-year period so that intermediate survey coincides with the second or third annual survey when the vessel is at the dock.

10. Cargo Ship Safety Equipment Certificate

– The survey leading to the issue of this certificate takes into account life saving and fire extinguishing appliances including fire detection and alarm, navigation equipment and publication, sound, light and distress signals, pilot ladder etc. Issued under SOLAS 74 the certificate used to be valid for 2 years but now under HSSC Protocol 88 it is issued for 5 years with provision for annual / intermediate survey.

A Record of Safety Equipment shall be attached to the Certificate.

11. Cargo Ship Safety Radio Certificate

– The survey leading to the issue of this Certificate to ships 300 GT and over will take into account

– The survey leading to the issue of this Certificate to ships 300 GT and over will take into account radio-communication and radio emergency / distress equipment. GMDSS requirement for unlimited voyages (covering areas A3 and A4) will involve a combination of at least two methods such as Duplication of equipment, shore-based maintenance (by contract) or at sea electronic maintenance capability (by having a qualified Radio-electronic Officer). Issued under SOLAS 74 the certificate used to be valid for one year but now under HSSC Protocol 88 it is issued for 5 years with provision for periodical inspection.

A Record of Safety Radio Equipment shall be attached to the Certificate.

12. Document of Authorization for Carriage of Grain:

– The document issued under SOLAS74 Reg. VI/9, MSC Resolution 23 (59) and Sec 3 of the International Code for the Safe Carriage of Grain in Bulk and shall accompany the Grain Loading Manual.

– The document issued under SOLAS74 Reg. VI/9, MSC Resolution 23 (59) and Sec 3 of the International Code for the Safe Carriage of Grain in Bulk and shall accompany the Grain Loading Manual.

13. Document of Compliance for the carriage of Solid Bulk Cargoes:

– Issued in compliance with International Maritime Sold Bulk Cargo Code (IMSB Code) and MSC 268(85). There shall be loading and unloading plan.

– Issued in compliance with International Maritime Sold Bulk Cargo Code (IMSB Code) and MSC 268(85). There shall be loading and unloading plan.

14. Bulk Carrier Booklet:

– To enable to Master to prevent excessive stress to the ship’s structure during loading and unloading of solid bulk cargoes, a booklet shall be provided as referred to in SOLAS Reg. VI/7 and the booklet shall be endorsed by the Administration or on its behalf to indicate that SOLAS regulations XII/4, 5, 6 and 7, as appropriate, are complied with. As an alternative to a separate booklet, the required information may be contained in the intact stability booklet.

15. Code of Safe Practice for Carrying Timber as Deck Cargo:

– This certification is done in compliance with 2011 TDC Code.

16. Document of Compliance for ships carrying Dangerous Goods (Packaged/ IMDG):

– Issued in compliance with SOLAS74 Reg. II-2/19 showing compartments and classes of cargoes.

– Issued in compliance with SOLAS74 Reg. II-2/19 showing compartments and classes of cargoes.

17. Dangerous Goods Manifest & Stowage Plan:

– Each ship carrying dangerous goods shall have a special list or manifest setting forth, in accordance with the classification set out in regulation VII/2, the dangerous goods on board and the location thereof. A copy of such list / manifest or stowage plan shall be made available to port state authority prior to proceeding to sea (SOLAS VII/5 (5)) and MARPOL 73/74 Annex III reg. 4) so that in

– Each ship carrying dangerous goods shall have a special list or manifest setting forth, in accordance with the classification set out in regulation VII/2, the dangerous goods on board and the location thereof. A copy of such list / manifest or stowage plan shall be made available to port state authority prior to proceeding to sea (SOLAS VII/5 (5)) and MARPOL 73/74 Annex III reg. 4) so that in

– Each ship carrying dangerous goods shall have a special list or manifest setting forth, in accordance with the classification set out in regulation VII/2, the dangerous goods on board and the location thereof. A copy of such list / manifest or stowage plan shall be made available to port state authority prior to proceeding to sea (SOLAS VII/5 (5)) and MARPOL 73/74 Annex III reg. 4) so that in case of an accident an immediate risk assessment can be made.

18. Cargo Securing Manual:

– Required in compliance with SOLAS74 Reg. VI/5, VII/5 and MSC.1/Circ.1353/Rev.1; and need to be approved.

– Required in compliance with SOLAS74 Reg. VI/5, VII/5 and MSC.1/Circ.1353/Rev.1; and need to be approved.

19. Stability Information Booklet:

– Master of every passenger ship (regardless of size) and every cargo ship of 24 meters and over shall be supplied with an approved stability Booklet containing such information as is necessary to enable, by rapid and simple procedures, to obtain guidance on ships range of stability under various loading conditions. (Ref: SOLAS 74 Reg. II – 1/22 and II – 1/25-8; LL Protocol 88 Reg. 10).

20. Damage Control Booklets:

– On passenger and cargo ships, there shall be permanently exhibited plans showing clearly for each deck and hold the boundaries of the watertight compartments, the opening therein with means of closure and position of any controls thereof, and the arrangements for the correction of any list due to flooding. Booklets containing the aforementioned information shall be made available to the officers (Bridge and Engine room) of the ship. (Ref: SOLAS 74 Reg. II-1/23, 23-1 and 25-8).

– On passenger and cargo ships, there shall be permanently exhibited plans showing clearly for each deck and hold the boundaries of the watertight compartments, the opening therein with means of closure and position of any controls thereof, and the arrangements for the correction of any list due to flooding. Booklets containing the aforementioned information shall be made available to the officers (Bridge and Engine room) of the ship. (Ref: SOLAS 74 Reg. II-1/23, 23-1 and 25-8).

21. Certificate of Fitness for Carriage of Dangerous Chemicals in Bulk:

– A certificate called a Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk, the model form of which is set out in the appendix to the Bulk Chemical Code, should be issued after an initial or periodical survey to a chemical tanker engaged in international voyages which complies with the relevant requirements of the Code. The Code is mandatory under Annex II of MARPOL 73/78 for chemical tankers constructed before 1 July 1986. (BCH Code, section 1.6; BCH Code as modified by resolution MSC.18(58) section 1.6).

22. International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk:

– A certificate called an International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk, the model form of which is set out in the appendix to the International Bulk Chemical Code (IBC Code), should be issued after an initial or periodical survey to a chemical tanker engaged in international voyages which complies with the relevant requirements of the Code. The Code is mandatory under both chapter VII of SOLAS 1974 and Annex II of MARPOL 73/78 for chemical tankers constructed on or after 1 July 1986. (IBC Code, section 1.5; IBC Code as modified by resolutions MSC.16(58) and MEPC.40(29), section 1.5).

23. Certificate of Fitness for the Carriage of Liquefied Gases in Bulk:

– A certificate called a Certificate of Fitness for the Carriage of Liquefied Gases in Bulk, the model form of which is set out in the appendix to the Gas Carrier Code, should be issued after an initial or periodical survey to a gas carrier which complies with the relevant requirements of the Code (GC Code, section 1.6). Certificate of Fitness for the Carriage of Liquefied Gases in Bulk is issued to Liquefied Gas Carriers built before 01-July-1986.

– A certificate called a Certificate of Fitness for the Carriage of Liquefied Gases in Bulk, the model form of which is set out in the appendix to the Gas Carrier Code, should be issued after an initial or periodical survey to a gas carrier which complies with the relevant requirements of the Code (GC Code, section 1.6). Certificate of Fitness for the Carriage of Liquefied Gases in Bulk is issued to Liquefied Gas Carriers built before 01-July-1986.

24. International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk:

– A certificate called an International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk, the model form of which is set out in the appendix to the International Gas Carrier Code, should be issued after an initial or periodical survey to a gas carrier which complies with the relevant requirements of the Code. The Code is mandatory under chapter VII of SOLAS 1974 for gas carriers constructed on or after 1 July 1986 (IGC Code, section 1.5; IGC Code as modified by resolution MSC.17 (58), section 1.5).

– A certificate called an International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk, the model form of which is set out in the appendix to the International Gas Carrier Code, should be issued after an initial or periodical survey to a gas carrier which complies with the relevant requirements of the Code. The Code is mandatory under chapter VII of SOLAS 1974 for gas carriers constructed on or after 1 July 1986 (IGC Code, section 1.5; IGC Code as modified by resolution MSC.17 (58), section 1.5).

25. Corrosion Prevention of Seawater Ballast tanks:

– Applies to oil tankers and bulk carriers (II-1 Part A-1, Reg. 3-2 of SOLAS74) built on or after 01 July 1998 and requires approval by or on behalf of the Administration. Guidelines are given in MSC.1/Cir.1330.

26. International Oil Pollution Prevention (IOPP) Certificate:

– Issued in compliance with Reg. 5 of Annex I of MARPOL 73/78 to tankers of 150 gt and above and other ships of 400 gt and above. The IOPP Certificate is of 5 years duration with provision for annual inspection and an intermediate survey coinciding with second or third annual survey.

The Certificate is supplemented by a Record of Construction and Equipment for ships other than Oil Tankers (Form A) or a Record of Construction & Equipment for Oil Tankers (Form B).

27. AFS Certificate or AFS Statement of Compliance or AFS Declaration: Ships (24 meters or more in length or 400 GT and above) will be required to carry one of the above documents (in compliance with the provisions of the International Convention on the Control of Harmful Anti-Fouling System, 2001).

28. International Pollution Prevention Certificate for Carriage of Noxious Liquid Substance in Bulk (INLS):

– Issued to ships carrying in bulk noxious liquid substances or un-assessed liquid substances under MARPOL 73/78 Annex – II Reg. 12 and 12a (unless holding a Certificate of Fitness as a Chemical Tanker). A Certificate of Fitness for Carriage of Dangerous Chemicals in Bulk under IBC code shall have the same recognition as the INLS Certificate. Both will contain the list of cargo the ship is allowed to carry.

– Issued to ships carrying in bulk noxious liquid substances or un-assessed liquid substances under MARPOL 73/78 Annex – II Reg. 12 and 12a (unless holding a Certificate of Fitness as a Chemical Tanker). A Certificate of Fitness for Carriage of Dangerous Chemicals in Bulk under IBC code shall have the same recognition as the INLS Certificate. Both will contain the list of cargo the ship is allowed to carry.

29. International Sewage Pollution Prevention Certificate:

– Certificate of Compliance: Prevention of Pollution by Sewage: An International Sewage Pollution Prevention Certificate shall be issued, after an initial or renewal survey in accordance with the provisions of regulation 4 of Annex IV of MARPOL 73/78, to any ship which is required to comply with the provisions of that Annex and is engaged in voyages to ports or offshore terminals under the jurisdiction of other Parties to the Convention (MARPOL 73/78, Annex IV, regulation 5; MEPC/Circ.408).

– Certificate of Compliance: Prevention of Pollution by Sewage: An International Sewage Pollution Prevention Certificate shall be issued, after an initial or renewal survey in accordance with the provisions of regulation 4 of Annex IV of MARPOL 73/78, to any ship which is required to comply with the provisions of that Annex and is engaged in voyages to ports or offshore terminals under the jurisdiction of other Parties to the Convention (MARPOL 73/78, Annex IV, regulation 5; MEPC/Circ.408).

30. Garbage Management Plan:

– Under MARPOL 73/78 Annex V Reg. 9, every ship 400 GT and above and every ship that is certified to carry 15 persons or more shall carry a garbage management plan that the crew shall follow. The ship shall also be provided with a Garbage Record Book.

31. International Air Pollution Prevention Certificate:

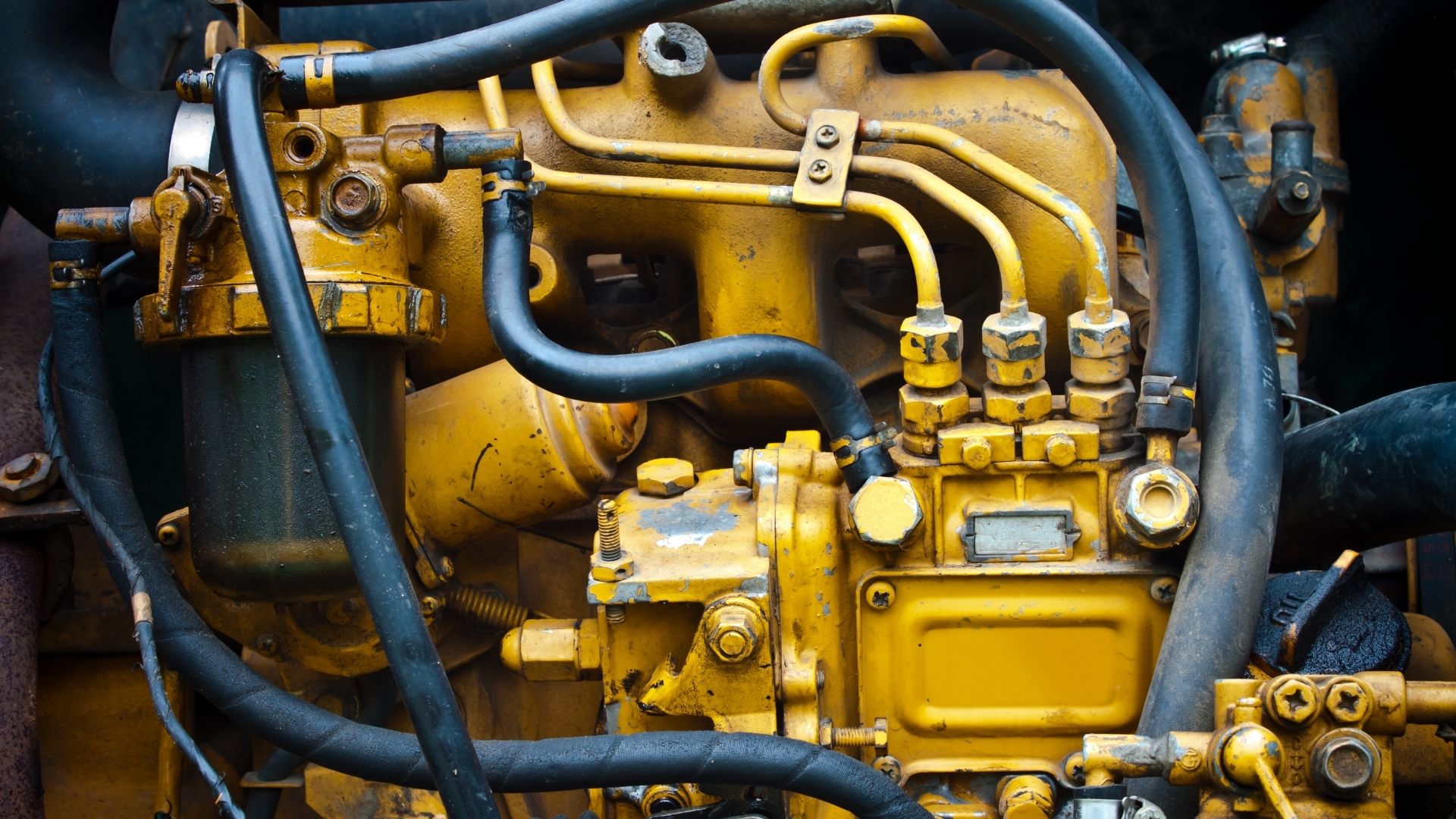

– Protocol relating to Annex VI to MARPOL – 73/78 on Prevention of Air Pollution from ships has been adopted in 1997. The Protocol requires diesel engines with more power than 130 kW on ships built after 01 January 2000 and incinerators on board ships to comply with the limits set for emission of Nitrogen Oxide and to be certified as per the requirement of Reg. 13 of the annex.

– Protocol relating to Annex VI to MARPOL – 73/78 on Prevention of Air Pollution from ships has been adopted in 1997. The Protocol requires diesel engines with more power than 130 kW on ships built after 01 January 2000 and incinerators on board ships to comply with the limits set for emission of Nitrogen Oxide and to be certified as per the requirement of Reg. 13 of the annex.

Protocol relating to Annex VI to MARPOL – 73/78 and certification of duel fuel engines under NOx Technical Code 2008 has been amended by MEPC.251 (66) and will be in force from 1st September 2015.

The Protocol also prescribes regulation for capping of Sulphur in bunker and emission of Sulphur Oxide in Emission Control Areas. Annex VI also lays the time table for phasing out the use of Halon and CFC.

For each fuel oil to be used on board a bunker delivery note has to be kept on board for at least 3 years and a representative sample of the bunkered fuel oil must be retained under the ship’s control until the fuel oil is substantially consumed, but in any case not less than 12 months. The representative sample of fuel oil must be sealed and signed by the supplier of the fuel oil and the master of the ship.

Every ship of 400 GT and above and every fixed and floating drilling rig and other platforms shall be surveys and issued with International Air Pollution and Prevention Certificate (IAPP).

Every ship of 400 gross tonnage, when Reg. 19 of this annex VI applies will also be surveyed and certified for International Energy Efficiency Certificate (IEE) after confirming that a ship specific Ship Energy Efficiency Management Plan (SEEMP) is available onboard as per Reg. 22 of this annex.

32. Ship Oil Pollution Emergency Plan (SOPEP):

– Required to be approved for tankers 150 GT & other ships 400 GT and over under MARPOL 73/78 Annex – 1 Reg. 37. (Guidelines – MEPC 54 (32) as amended by resolution MEPC.86 (44)). SOPEP forms a part of the SMS.

33. Shipboard Marine Pollution Emergency Plan for Noxious Liquid Substances (SMPEP)

– From 01 January 2003 under MARPOL 73/78 Annex II, Reg. 17 every ship of 150 GT and above certified to carry noxious liquid substances in bulk shall carry on board approved marine pollution emergency plan (SMPEP) for noxious liquid substances. This may be a combined document with SOPEP complying with the requirements of resolution MEPC.85 (44), as amended by resolution MEPC.137 (53).This forms a part of the SMS.

34. Procedure & Arrangements Manual

– Every ship certified to carry noxious liquid substances in bulk (MARPOL Annex-II Reg. 14) should have on board approved P&A manual.

35. Cargo Record Book

– Required under MARPOL 73/78 Reg. II/15.

36. Oil Record Book

– Required under MARPOL73/78 Annex I Reg. 17 & 36; Part I for Machinery (tankers 150 GT and above; and other vessels 400 GT and above) and Part II for cargo / ballast operation (tankers only 150 GT and above).

37. Record of Oil discharge monitoring and control system for Ballast Voyage (ODME):

Subject to provisions of paragraphs 4 and of Reg. 3 of Annex I of MARPOL 73/78 every oil tanker of 150 GT and above shall be fitted with approved oil discharge monitoring and control system. The system shall be fitted with a recording device to provide a continuous record of discharge in liter per nautical mile and total quantity discharged, or the oil content and rate of discharge. The record shall be identifiable as to time and date and be kept for at least 3 years.

38. Permanent Means of Access/ Access Manual

– Tankers and Bulk Carriers (constructed on or after 01-1-05) are required to have approved Ship Structure Access Manual for easy access and inspection of all parts and structures (SOLAS II-1/3-6; MSC.Circ.1107 and MSC.1/Circ. 1464/Rev.1).

39. Safe Manning Document

– Issued in compliance with SOLAS74 Reg. V/14 (2) and A-1047 to ships engaged in international voyages showing the minimum number and category of seafarers required for safe operation of the vessel.

40. Muster List

– Required under SOLAS74 Reg. III/37. The Muster List for passenger ships shall be on a format approved by the Administration. The Muster List must show the duty station of each person in emergency with a dedicated team for Damage Control/ Incident/ Quick Response while a small team for advance preparation of LSA.

41. ISM – Document of Compliance (DOC)

– Issued to the Company/Operator in compliance of Chapter IX of SOLAS74 and ISM Code specifying the types of ships the company has been found competent to operate. The DOC will have a validity of 5 years subject to periodical (annual) endorsement of verification.

42. ISM – Safety Management Certificate (SMC)

– Issued to ships in compliance with Chapter IX of SOLAS74 and ISM Code after necessary verification and audit that there is a Safety Management System in place and that the company has valid DOC for the relevant type of ship. The SMC is valid for 5 years subject to an intermediate verification.

43. Training Manual

– Required under SOLAS74 Chapter III (Section V) Reg. 35. This is a simplified guidance brochure on the use of the type of safety equipment used on the ship. It is normally kept in the Crew Mess.

44. Instruction for on-board maintenance

– Required under SOLAS74 Chapter III (Section V) Reg. 36.

45. Fire control plans –

This is required under SOLAS74 Reg. II-2/15.2.4. General arrangements shall be permanently exhibited for the guidance of the ship’s officers showing clearly for each deck – control stations, sections enclosed by “A” class divisions, sections enclosed by “B” class divisions together with particulars of the fire detection and alarm system, the sprinkler installation, fire-extinguishing appliances, means of access and the ventilating system, including particulars of the fan control positions, location of dampers and identification numbers of the ventilating fans serving each section.

The aforementioned details may be set out in a booklet, a copy of which shall be supplied to each officer, and one copy shall at all times be available on board in an accessible position. Plans and booklets shall be kept up-dated (corrected for any changes).

A duplicate set of fire control plans or booklet containing such plans shall be permanently stored in a prominently marked weather-tight enclosure outside the deck-house (near to the gangway) for the guidance of the shore-side fire-fighting personnel.

46. Decision Support System –

In passenger ships, a printed emergency plan covering all foreseeable emergency situations shall be provided on the navigation bridge for the guidance of the master (SOLAS74 Reg. III/29).

47. Search and Rescue Co-operation Plan

– Passenger ships to which chapter I of SOLAS applies, trading on fixed routes, shall have on board a plan for co- operation with appropriate SAR services in the event of an emergency; Ref: SOLAS V/7.3.

48. Certificate of Insurance in respect of Oil Pollution Damage

– Required under Article VII of the International Convention on Civil Liability for Oil Pollution Damage, 1992 (CLC) by owner of a tanker which carries more than 2000 tons of oil in bulk. The Administration normally issues this Certificate as an endorsement of an insurance cover, which run from 20 February to 20 February.

49. Certificate of Insurance in respect of Bunker Oil Pollution Damage –

Required under Article VII of the International Convention on Civil Liability for Bunker Oil Pollution Damage, 2001 (CLC) by a registered owner of a ship having gross tonnage greater than 1000 registered in a state party of this convention. The Administration normally issues this Certificate as an endorsement of an insurance cover, which runs from 20 February to 20 February.

50. Certificate of Financial Responsibility –

Required by all ships to operate in the US waters to confirm that the ship can meet its financial obligation in respect of any pollution caused by the ship.

With effect from 06 April 2001 Australia has also introduced a requirement of compulsory insurance for all vessels of 400 Gt. or more (other than CLC which already applies to tankers) to cover any pollution damage in Australian waters. A P&I cover is acceptable.

51. High Speed Craft Safety Certificate –

Issued under SOLAS74 Reg. X/3 and HSC Code paragraph 1.8.

52. Permit to operate High Speed Craft –

Issued under HSC code paragraph 1.9.

53. Ship Sanitation Control Certificate/ Ship Sanitation Control Exemption Certificate (SSCC/ SSCEC) –

With effect from 15-June-2007 in compliance with International Health Regulations 2005 (Ship sanitation control provisions in Articles 20, 27, 39 and Annex 3) a ship will be required to have either a SSCC or SSCEC valid for a period of six months. This will replace the old deratting or deratting exemption certificate issued under IHR 1969.

54. On-board Health Care –

Every ship over 500 GT with a crew of 15 or more persons intended for sea voyages exceeding three days shall have a hospital in accordance with the provisions of ILO Convention Nos. 164 and shall have a Medical Chest complying with the requirements of Health Protection and Medical Care (Seafarers) Convention 1987 and International Medical Guide for Ships (WHO / ILO / IMO). The Medical Chest must be checked and certified annually by a Marine Pharmacist approved by the Administration. Ship must also maintain record of all medical treatment provided on board. It is now covered by new ILO-MLC 2006.

55. Ship’s Radio Licence –

National Telecommunication Authority may require the ships to have a licence to install, maintain and operate the radio station. The ship shall be allocated a call sign and MMSI number.

56. Life-raft Servicing Certificate –

Life-rafts are required to be serviced (including change of equipment and emergency ration when so required) once every 12 months (plus/ minus 3 months window) by approved service stations and certificates must be retained on board. Extension may be granted up to 5 months (but duration from last servicing must not exceed 18 months).

57. Cargo and Hoisting gear Certificate –

It originates from ILO convention (No. 152). National requirements are normally found in Factories Act, Health and Safety Act or Occupational Safety Act. Test certificates in respect of wires, chains, blocks, pulley, shackles and other hoisting gear (including cranes and derricks) are to be maintained. This is in addition to the Anchor and Chain Certificates.

Regulation III-20 of SOLAS 74 requires all davits along with winches of the lifeboats and life-raft (with launching device) must be load tested once every 5 years.

58. Crew Accommodation Certificate –

Requirements of space, ceiling height lighting, ventilation, heating, wash and toilet facilities are given in the ILO Convention (No. 92 & 133). Accommodation plans are normally approved prior to the building of the ship. In other case survey and certification is done by or on behalf of the Flag Administration prior to the registration of the vessel. It is now covered by new ILO-MLC 2006.

59. Noise level Certificates –

The requirement of this survey report is mentioned in A-468 Sec. 4.3 (to be done in accordance with the Code of Noise Levels on board ships).

60. Deviation Card and Record –

Deviation card issued by the Compass Adjuster (after necessary swing) must be retained on board along with compass error and deviation found on different heading at different times (with different cargo).

61. Servicing, pressure test and recharging –

Portable Fire Extinguishers must be inspected annually and test discharged at least once every 5 years. Cylinders used in portable fire extinguishers must be hydraulically tested at least once every 10 years (A-602; now A-951). Sufficient refills shall be carried on board so that at least 50% of each type of portable extinguishers can be recharged on board in case of their use or accidental discharge.

Portable Fire Extinguishers must be inspected annually and test discharged at least once every 5 years. Cylinders used in portable fire extinguishers must be hydraulically tested at least once every 10 years (A-602; now A-951). Sufficient refills shall be carried on board so that at least 50% of each type of portable extinguishers can be recharged on board in case of their use or accidental discharge.

CO2 cylinders used in fixed installation must be inspected every year and checked for level/ content. If there is loss of content by 10% or more then it must be refilled. The fixed installation system must be serviced by approved/ authorized service agents once every two years. Cylinders used in fixed installation should be inspected for any damage or corrosion; and if found in satisfactory condition, it may remain in operation for 20 years before a pressure test is done. Subsequent pressure testing should be done at five yearly intervals.

As per EU requirement, system containing Halon shall not be recharged after 31 December 2002 and Halon based system must be phased out by 31 December 2003. Ships trading perpetually within EU may have to comply with this requirement.

Record of recharging, level check, refill, servicing and pressure test must be maintained in the “On-board Maintenance Record Book” or a Record Book used exclusively for this purpose in addition to necessary markings in respective cylinders/ extinguishers.

See more details in MSC.1/Circ.1432.

62. Seafarers’ Employment Agreements

– Each seafarer employed on the ship which Maritime Labour Convention 2006 applies must have a legally enforceable Seafarers’ Employment Agreement (SEA). The agreement must have minimum information as mentioned in the Reg. 2.1 and Standard A2.1 of the convention and may include additional clauses required by the Flag Administration or those mutually agreed between the employer and the employees or collective bargaining agreement (CBA) endorsed by the social partner (Union).

Each seafarer employed on the ship which Maritime Labour Convention 2006 applies must have a legally enforceable Seafarers’ Employment Agreement (SEA). The agreement must have minimum information as mentioned in the Reg. 2.1 and Standard A2.1 of the convention and may include additional clauses required by the Flag Administration or those mutually agreed between the employer and the employees or collective bargaining agreement (CBA) endorsed by the social partner (Union).

The convention relating to Articles of Agreement has provisions for issue of document to seafarers for record of service performed on each ship. This document is commonly referred to as Discharge Book or Continuous Discharge Certificates (CDC). Sometimes the Discharge Book is combined with Seafarers’ Identity Document (ILO No. 108 of 1958).

The seafarer’s Identity Document, Crew Agreement and the Discharge Book along with appropriate reference letter from the Administration or the employer are sometimes accepted for travel purpose to join a ship or to get back to the country of origin on completion of the tenure of service on a ship. However, a Passport with Visa where so necessary remains the internationally accepted travel document.

63. Seafarer’s Identity Document (ILO-185 of 2003) –

Seafarers are required to hold SID issued by their national administration and the issuing authority shall maintain an electronic data base. This document is a “stand-alone” document and cannot be mixed up with any other document.

64. Labour inspection –

ILO Convention No. 178 known as “Labour Inspection (Seafarers) Convention, 1996” requires the Flag Administration to inspect seafarers’ working and living conditions at intervals not exceeding 3 years. The guidelines for the inspection are given in “Labour Inspection (Seafarers) Recommendation, 1996 (No. 185)”. It is now absorbed by new ILO-MLC 2006.

Administrations that do not delegate ISM-SMC audit and certification to classification societies and conduct it themselves will find it very convenient to undertake the labour inspection coinciding with ISM-SMC audit (once every 30 months).

65. Seafarers’ Training Document –

Deck, Engineer and Radio Officers must hold appropriate Certificates of Competency (duly endorsed by the Administration) as required under STCW Convention. All ratings must hold Basic Training Certificate (4 elements outlined in A-VI/1). The Deck and Engine-room ratings must hold appropriate Watch-rating Certificates. If the ship employs Electro-technical Officer, Electro-technical Rating, Able Seafarer (Deck) and Able Seafarer (E/R) then they must be duly qualified under the Convention. Ship’s Cook Certificate is issued under ILO Convention No.69. This qualification is likely to be covered in future by the STCW Convention.

Officers and ratings assigned specific duties related to cargo or cargo equipment on tankers are required to be in possession of Certificate/Document in respect of “Tankers Familiarization Training”. Master, Chief Engineer Officer, Chief Mate, Second Engineer Officer and any person with immediate responsibility for loading, discharging and care in transit or handling of cargo on a tanker shall be required, in addition to the requirements stated above, to be in possession of a Tanker Endorsement for relevant type of tanker. Tanker Certificate or Tanker Endorsement shall only be given to officers who have undertaken Specialized Tanker Training (in addition to Tanker Familiarization) and have performed a period of service on relevant type of tanker. The final document shall be issued by a Party Administration.

Officers, ratings and other personnel who are designated on Muster List to assist passengers in emergency situation shall have received training in i) Crowd Management ii) Familiarization and iii) Direct Service to passengers. Master, Chief Engineer, Chief Mate, Second Engineer Officer and others with immediate responsibility for embarking/disembarking of passengers or loading, discharging and securing of cargo and having responsibility for safety of passengers shall have received, in addition to the training referred to above, approved training in iv) Passenger Safety, Cargo Safety and Hull integrity and v) Crisis Management and Human behavior.

The Administration issuing final certificate/ endorsement/ document shall maintain electronic data base in such manner that can be directly verified by another Administration (from 2017).

Persons in charge of survival craft must hold CPSC & RB.

Persons serving on HSC shall have type-rating certificates (HSC Code 18.3.3) and those on Off-shore units shall have training documents under A-891.

66. Seafarers’ Medical Fitness

– Required under Reg. I/9 and 1/14 of STCW95. More details are available in ILO Convention No. 73. It is also covered by new MLC 2006.

Required under Reg. I/9 and 1/14 of STCW95. More details are available in ILO Convention No. 73. It is also covered by new MLC 2006.

67. Official log book

– Any accident, death, birth, major breakdown or accidental damage, shipboard Boat and Fire drills, Opening and Closing of W/T doors or any incident of significant importance must be duly recorded. However, day to day routine operational and maintenance matters are recorded in Deck, Engine and Radio (GMDSS) Log Books. Ships should also maintain

Any accident, death, birth, major breakdown or accidental damage, shipboard Boat and Fire drills, Opening and Closing of W/T doors or any incident of significant importance must be duly recorded. However, day to day routine operational and maintenance matters are recorded in Deck, Engine and Radio (GMDSS) Log Books. Ships should also maintain record of medical treatment given on board. Oil Record Book must be kept up to date. Official log book is a national matter.

68. Enhanced Survey Report File

– Bulk carriers and oil tankers shall have a survey report file and supporting documents complying with paragraphs 6.2 and 6.3 of annex A and annex B of resolution A.744 (18) – Guidelines on the enhanced programme of inspections during surveys of bulk carriers and oil tankers (SOLAS 1974 (2002 Amendments.) regulation XI-1/2; resolution A.744(18)). Application to FPSO and FSU can be found in MEPC Circ. 406.

Bulk carriers and oil tankers shall have a survey report file and supporting documents complying with paragraphs 6.2 and 6.3 of annex A and annex B of resolution A.744 (18) – Guidelines on the enhanced programme of inspections during surveys of bulk carriers and oil tankers (SOLAS 1974 (2002 Amendments.) regulation XI-1/2; resolution A.744(18)). Application to FPSO and FSU can be found in MEPC Circ. 406.

69. Special Purpose Ship Safety Certificate

– A Certificate may be issued under the Code of Safety for Special Purpose Ships 2008 (2008 SPS Code) and A534 (13) as amended by resolution 299(87).

A Certificate may be issued under the Code of Safety for Special Purpose Ships 2008 (2008 SPS Code) and A534 (13) as amended by resolution 299(87).

70. Certificate for Offshore Supply Vessels

– Surveyed and certified as per paragraph 1.5 of Resolution A673 (16), as amended by MEPC 158(55), MSC 184(79) & MSC 236(82).

Surveyed and certified as per paragraph 1.5 of Resolution A673 (16), as amended by MEPC 158(55), MSC 184(79) & MSC 236(82).

71. Diving System Safety Certificate

– Issued in compliance with “Code of Safety for Diving System 1995” (Res. A-831(19)). A 692 (17) contain guidelines for evacuation.

Issued in compliance with “Code of Safety for Diving System 1995” (Res. A-831(19)). A 692 (17) contain guidelines for evacuation.

72. Dynamic Positioning System

– Details given in IMO MSC Circular 645. Vessel so fitted may be certified accordingly. The certificate is also known as “Flag State Verification and Acceptance Document”.

73. Mobile Offshore Drilling Units Safety Certificate

– The code for the Construction and Equipment of Mobile Offshore Drilling Units 2009, A26/ Res 1023. Manning and training for MOU (Mobile Offshore Units)

The code for the Construction and Equipment of Mobile Offshore Drilling Units 2009, A26/ Res 1023. Manning and training for MOU (Mobile Offshore Units) is covered by Res A. 891(21).

74. Construction & Equipment Certificate for Dynamically Supported Craft

– The Code of Safety for Dynamically Supported Craft and A-373 Section 1.6.

A permit to operate (specifying route, destination and limitations) may be issued under DSC Code (similar to Permit to Operate a HSC).

75. International Load Line Exemption Certificate –

May be granted under Article 6 of LL66 and Article 18 of LL Protocol 1988.

76. Exemption Certificate

– May be granted under Reg. I/4 of SOLAS 74 as amended and similar enabling provisions in other Conventions and Protocols.

77. Crew list, Stores lists, Cargo manifest and Crew declaration

– Required by local port authority, immigration and customs on arrival of the ship.

78. Record of PSC

– It makes good sense to keep on board record of previous “Port State Control” Inspection reports so that the Port State Surveyor/Inspector gets a clear picture of the situation. PSC may be exercised individually by a Port/ Coastal State or through regional co-operation such as Paris MOU. IMO Resolutions A. 1052(27) and UK-MCA MSN 1832 provide necessary guidance. SOLAS74 regulation XI-I/4 allows PSC to check on operational requirements.

It makes good sense to keep on board record of previous “Port State Control” Inspection reports so that the Port State Surveyor/Inspector gets a clear picture of the situation. PSC may be exercised individually by a Port/ Coastal State or through regional co-operation such as Paris MOU. IMO Resolutions A. 1052(27) and UK-MCA MSN 1832 provide necessary guidance. SOLAS74 regulation XI-I/4 allows PSC to check on operational requirements.

79. Certificate of Class

– It is not a requirement under any international convention (though new SOLAS II-1 Part A-1 regulation 3-1 requires ships to be built and maintained in compliance with Class Society requirements). There are very few countries where classification is a mandatory requirement. However, owners will evidently have their ships classed for market credibility and also for

It is not a requirement under any international convention (though new SOLAS II-1 Part A-1 regulation 3-1 requires ships to be built and maintained in compliance with Class Society requirements). There are very few countries where classification is a mandatory requirement. However, owners will evidently have their ships classed for market credibility and also for convenience of survey facilities around the world. Class records are a helpful tool to ascertain the general condition of a ship.

80. Harmonised System of Survey and Certification (HSSC)

– The 1988 Protocols to SOLAS74 and LL66 harmonizes the survey and certification system to common period of validity cycle creating possibility for cargo ships to eventually have a combined Safety Certificate incorporating Safety Construction, Safety

The 1988 Protocols to SOLAS74 and LL66 harmonizes the survey and certification system to common period of validity cycle creating possibility for cargo ships to eventually have a combined Safety Certificate incorporating Safety Construction, Safety Equipment and Safety Radio or to have three separate Safety Certificates but with common period of validity for 5 years with provision for annual/intermediate survey. In respect of Safety Radio and SEC the term periodical survey (instead of annual) has been used which implies complete examination of all items. In all cases the Certificates will have a Record of Equipment attached.

With regard to LL66 the protocol harmonizes the intact stability requirements of certain cargo ships in line with MARPOL 73/78.

Reference has also been made to Additional Survey, which implies an Inspection, general or partial following a repair. Further guidance is given in IMO Res. A-833, A-746 and the UK-MCA MSN 1751.

81. Inspection of the outside of the ship’s bottom –

There is a general requirement for inspection of the outside of the ship’s bottom at least twice in any five year period at intervals not exceeding 36 months between two such inspections. In the case of passenger ships, these inspections will have to be undertaken in dry dock with the vessel being out of the water. An in-water survey (IWS) of the underwater part (by an organization approved by or on behalf of the Administration and done under the supervision of the RO) shall be made annually when the vessel is not docked. This means to say that a dry dock report or an IWS report shall be available every year at the time of the issue / renewal of the Passenger Ship Safety Certificate.

In cargo ships, the requirements for the survey of underwater part of the hull (twice within five-year period of the SAFECON certificate and at intervals not exceeding 36 months between two such inspections) can be done as IWS provided that every alternate one is done in dry dock. This will mean, in case of cargo ships, the outside of the ship’s bottom shall be inspected twice in any five year period, at least one of them being in dry dock. In practice, it may fit well with renewal and intermediate survey.

However, tankers and bulk carriers of over 15 years of age must be dry docked instead of IWS.

82. Phasing out single hull tankers –

In December 2003 IMO adopted a revised, accelerated phase-out scheme for single hull tankers, along with other measures including an extended application of the Condition Assessment Scheme (CAS) for tankers and a new regulation banning the carriage of Heavy Grades of Oil (HGO) in single-hull tankers. The amendments to the International Convention for the Prevention of Pollution from Ships, 1973, as modified by the Protocol of 1978 relating thereto (MARPOL 73/78) entered into force on 5 April 2005.

Under a revised regulation 13G of Annex 1 of MARPOL, the final phasing-out date for Category 1 tankers (pre-MARPOL tankers) is brought forward to 2005, from 2007. The final phasing-out date for category 2 and 3 tankers.

Under the revised regulation, the Condition Assessment Scheme (CAS) is to be made applicable to all single-hull tankers of 15 years, or older. Previously it was applicable to all Category 1 vessels continuing to trade after 2005 and all Category 2 vessels after 2010. Consequential enhancements to the CAS scheme were also adopted.

The revised regulation allows the Administration (Flag State) to permit continued operation of category 2 or 3 tankers beyond 2010 subject to satisfactory results from the CAS, but the continued operation must not go beyond the anniversary of the date of delivery of the ship in 2015 or the date on which the ship reaches 25 years of age after the date of its delivery, whichever is earlier.

In the case of certain Category 2 or 3 oil tankers fitted with only double bottoms or double sides not used for the carriage of oil and extending to the entire cargo tank length or double hull spaces which are not used for the carriage of oil and extend to the entire cargo tank length, the Administration may allow continued operation beyond 2010, provided that the ship was in service on 1 July 2001, the Administration is satisfied by verification of the official records that the ship complied with the conditions specified and that those conditions remain unchanged. Again, such continued operation must not go beyond the date on which the ship reaches 25 years of age after the date of its delivery.

Carriage of heavy fuel oils

A new MARPOL regulation 13H on the Prevention of oil pollution when carrying heavy grades of oil (HGO) bans the carriage of HGO in single-hull tankers after the expected date of entry into force of the regulation (4 April 2005). Under the new regulation, HGO means any of the following:

a) Crude oils having a density at 15ºC higher than 900 kg/m3;

b) Fuel oils having either a density at 15ºC higher than 900 kg/m3 or a kinematic viscosity at 50ºC higher than 180 mm2/s;

c) Bitumen, tar and their emulsions.

Regulation 13(H) does, however, allow for continued operation of oil tankers of 5,000 tons deadweight and above, carrying heavy oils with a density at 15ºC higher than 900 kg/m3 but lower than 945 kg/m3, if satisfactory results of the Condition Assessment Scheme warrant that, in the opinion of the Administration, the ship is fit to continue such operation, having regard to the size, age, operational area and structural conditions of the ship and provided that the continued operation shall not go beyond the date on which the ship reaches 25 years after the date of its delivery.

The Administration may allow continued operation of a single hull oil tanker of 600 tons deadweight and above but less than 5,000 tons deadweight, carrying heavy grade oil as cargo, if, in the opinion of the Administration, the ship is fit to continue such operation, having regard to the size, age, operational area and structural conditions of the ship, provided that the operation shall not go beyond the date on which the ship reaches 25 years after the date of its delivery.

The Administration of a Party to the present Convention may exempt an oil tanker of 600 tons deadweight and above carrying heavy grade oil as cargo if the ship is either engaged in voyages exclusively within an area under the Party’s jurisdiction, or is engaged in voyages exclusively within an area under the jurisdiction of another Party, provided the Party within whose jurisdiction the ship will be operating agrees. The same applies to vessels operating as floating storage units of heavy grade oil.

Flag State May Permit Extended Operation

Under the amended regime flag states can permit continued operation of category 2 or 3 tankers beyond 2010 subject to a satisfactory CAS, but the continued operation must not go beyond the anniversary of the date of delivery of the ship in 2015 or the date on which the ship reaches 25 years of age after the date of its delivery, whichever is earlier.

In the case of certain Category 2 or 3 oil tankers fitted with only double bottoms or double sides not used for the carriage of oil and extending to the entire cargo tank length or double hull spaces which are not used for the carriage of oil and extend to the entire cargo tank length, flag states may allow continued operation beyond 2010, provided that the ship was in service on 1 July 2001, the flag state is satisfied by verification of the official records that the ship complied with the conditions specified and that those conditions remain unchanged. Again, such continued operation must not go beyond the date on which the ship reaches 25 years of age after the date of its delivery.

Port State May Deny Entry

Even where single hull tankers which have been allowed to continue operation by their flag state under the exemptions mentioned above the amended regime allows a port state the right to deny entry to such vessels into ports or offshore terminals under its jurisdiction, and to deny ship-to-ship transfer of heavy grade oil in areas under its jurisdiction except when this is necessary for the purpose of securing the safety of a ship or saving life at sea.

83. Renewal Survey and validity of certificates

If the renewal survey is carried out within a period of 3 months before the expiry of the existing certificate then the new certificate can be issued on completion of the relevant survey and will have a validity of 5 years (one year in case of passenger ships) from the date of expiry of the existing certificate.

If the renewal survey is carried out within a period of 3 months before the expiry of the existing certificate then the new certificate can be issued on completion of the relevant survey and will have a validity of 5 years (one year in case of passenger ships) from the date of expiry of the existing certificate.

If the renewal survey is carried out more than 3 months before the expiry date of the existing certificate then the new certificate can be issued on the day the survey is completed but it will have a validity of no more than 5 years (one year in the case of passenger ships) from the date of completion of the survey.

In exceptional circumstances where a renewal survey is carried out after the expiry date of the existing certificate, the new certificate can be issued on the day the survey is completed and will have a validity of 5 years (one year in the case of passenger ships) from the date of expiry of the previous certificate.

If for some reason a new certificate cannot be issued on completion of survey then the existing certificate may be endorsed as valid for a further period of 5 months (from the expiry date).

The Administration may extend the period of validity of an existing certificate (other than passenger ship safety certificate) by no more than 3 months to allow the ship to reach the intended port of survey.

84. Existing Ship changing flag –

When ships change Flag, all statutory certificates issued by or on behalf of the previous Administration stand void. It is the responsibility of the flagging in Administration to issue the vessel with necessary statutory documents. However, it should not be necessary to start a new survey cycle. Subject to satisfactory completion of the survey, certificates can be issued with the same expiry date as shown in previous certificates. However, a clarification letter should accompany the certificates so that the original schedule for annual / intermediate survey / audit can be maintained.

It is also necessary to ensure that all radio-electronic equipment is duly programmed. Ships are required to have nine digit MMSI numbers. EPIRBs are required to be programmed and registered. EPIRBs are now required to be serviced every year in addition to the servicing of the HRU units.

85. Recent introductions –

a) Emergency Escape Breathing Devices:

Applies to all vessels, in accordance with the SOLAS guidelines a number of EEBDs are required to be carried. The number and location should be shown in the Fire Control Plan. This new requirement will henceforth be a part of the safety equipment survey.

b) Voyage Data Recorder (VDR):

Required under regulation 20 of chapter V of SOLAS74. See A.861 (20) for specification requirements and IEC Standard No. 61996 for testing standards. The requirements entered into force in the following phases of first survey after 01-07-2002.

Passenger ships constructed on or after 01-7-02;

Ro-Ro Passenger ships even if built before 01-7-02;

Other passenger ships built before 01-7-02 by 01-1-04;

Cargo ships 3000 GT and above built on or after 01-7-02 by 01-1-04.

Cargo ships of 20,000 gross tonnage and upwards constructed before 1 July 2002, at the first scheduled dry-docking after 1 July 2006 but not later than 1 July 2009;

Cargo ships of 3,000 gross tonnage and upwards but less than 20,000 gross tonnage constructed before 1 July 2002, at the first scheduled dry-docking after 1 July 2007 but not later than 1 July 2010; and

Administrations may exempt cargo ships from the application of the requirements of subparagraphs above when such ships will be taken permanently out of service within two years after the implementation date specified in subparagraphs.

It will be necessary to carry on board Performance test and report (annual) in respect of VDR.

c) Automatic Identification System (AIS):

It shall be fitted to all ships of 300 GT and upwards engaged on international voyages and cargo ships of 500 GT and upwards even if not engaged in international voyages, and passenger ships irrespective of size, as follows:

All ships constructed on or after 01-July-2002.

All passenger ships engaged on international voyages not later than 01-July-2003.

All tankers engaged on international voyages not later than the first safety equipment survey after 01-July-2003.

All ships of 50,000 GT and upwards on international voyages not later than 01-July-2004.

All ships between 300 GT and 50000 GT on international voyages not later than the first Safety Equipment survey after 01-July-2004 or by 31-December-2004, whichever occurs first.

Ships fitted with AIS shall have AIS in operation at all times, except where International agreements, rules or standards provide for the protection of navigation information.

d) Electronic Chart Display & Information System (ECDIS): SOLAS-74 Regulation V-19.2 requires every ship to be fitted with ECDIS.

e) Long Range Identification & Tracking (LRIT):

The requirements (SOLAS – V/19-1) entered into force on 01-January-08 and the International Data Exchange (IDE) shall be operational on 01-July-08. The Data Distribution Plan (DDP) should be functional from 31-December-08. It shall apply to all Passenger ships, Cargo ships 300 GT and above and Mobile Offshore Drilling Units unless Operating within A1 area and fitted with AIS from First Radio Survey after 31-December-08. It should be capable of making four reports daily to include ship’s ID (IMO & MMSI Number), Position, date and time. Flag State can have a quick glance on the position of its ships. SAR requests are free. IMO has appointed IMSO as the LRIT coordinator.

LRIT is a Maritime Domain Awareness (MDA) that allows a Member State to monitor and track vessels operating in proximity of its coastline. MDA provide – enhanced security, environmental protection and safety/ search and rescue benefits. The basis of LRIT system is that all ships will automatically report their identity and position to a receiving entity every six hours.

Member States may – have National Data Centre (NDC) to service own flagged vessels;

Participate in Regional Data Centre (RDC) for two or more Member States’ Flag vessels;

Participate in an International Data Centre (IDC) that would provide services to all Member States not using NDC or RDC.

[Bahrain has contracted the services of a commercial data centre provider known as Pole Star (www.polestarglobal.com). Bahrain registered vessels to which the LRIT regulation applies work with Pole Star directly to ensure their 6 hourly reports are received and forwarded as required to the IDE.]

86. Member State Audit:

From 01-January-2016 this requirement shall come into force. Each Member State shall have to provide evidence of having legal, administrative and other arrangements in place to effectively enforce the applicable requirements of IMO.

87. International Ship Security Certificate:

A new chapter XI/2 has been added to SOLAS to introduce the International Ship and Port Security Code (ISPS Code). The Code will have mandatory Part A and recommended guidance on Part B. Ships will be required to have an approved Security Plan. A certificate known as “International Ship Security Certificate” will have to be issued. The certificate will have validity for 5 years and will have an intermediate endorsement (like the ISM-SMC). The requirements came into force on 01 July 2004.

Existing ships coming into register may be issued with interim certificate valid for 6 months provided the ship i) has a plan; ii) fitted with alarm and iii) has a trained security officer. The ships should also obtain a CSR.

88. Continuous Synopsis Record:

The Administration shall, as part of the newly introduced security measure, issue a Continuous Synopsis Record for the purpose of providing an on board record of the history of the ship with respect to the information recorded therein. The record shall contain at least the following particulars:

- Name and IMO number of the ship;

- The Flag and Port of Registry;

- Date when registered;

- Name and particulars of the owners;

- Name and particulars of the Bare-boat charterers, if any;

- Name and particulars of any Time charterer or Voyage charterer;

- Name and particulars of the company responsible for safe operation and protection of the environment (ISM Company);

- The recognized organization with which the vessel is classed;

- The organization that issued the ISM and ISPS certification;

- History of the ship (outlined above) from 01-July-04

89. Requirement of Publications:

Ships are required to carry on board:

- Navigational Charts (corrected & up-dated)

- Notices to Mariners

- Annual Notices to Mariners

- IMO Ship’s Routeing

- Sailing Directions/ Pilots

- Ocean current/ Tidal Stream Atlases

- Tide tables

- List of Lights

- List of Radio Signals

- Navigational tables (Almanac and Nories tables)

- International Code of Signals

- IAMSAR – Manual Vol.-III

- International (IMO/ ILO/ WHO) Medical Guide

- MFAG and EmS – if ship certified to carry dangerous goods

Codes (e.g. HSC, DSC, IBC, BCH, IGC, MODU etc) applicable to the ship

- ILO Code of Practice for Accident Prevention or UK-MCA Code of Practice for Merchant Seamen

- Operation and Maintenance instruction/ Manual for Navigational

- Aids carried on board

- ISM Procedure manuals.

- National Merchant Shipping Legislation

Ships shall also carry on board:

- Certificate of Registry

- Seafarers’ Employment Agreement for all crew / Article of

- Agreement (for non MLC ships)

- Official Log Book

- GMDSS Log Book

- Oil Record Book

- Statutory certificates (under international instruments) applicable to the ship

Other publications recommended to be carried on board:

- Latest/ up-dated version of LL, SOLAS, MARPOL, STCW and COLREG

- Mariners’ Handbook

- MSN and MGN (UK-MCA).

90. Gross weight of containers:

It is now mandatory that each container destined for loading on a ship must have a certificate of Gross weight. This requirement must be viewed from

It is now mandatory that each container destined for loading on a ship must have a certificate of Gross weight. This requirement must be viewed from safety point of view for assessing correct stability and not from commercial view point.

91. Ballast Water Management (BWM):

The ballast water of ships carries plants and animals which frequently settle in foreign sea regions, representing a danger for the indigenous flora and fauna with the potential to cause great ecological and economic damage. An approved “Ballast Water Management Plan” will regulate the procedures for preventing the exchange of marine organism. The necessary measures will involve exchanging the ballast water on the high seas and, in future, treatment of the ballast water by heating, filtration or even chemical process. The International Convention for the Control and Management of Ship’s Ballast and Sediments (BWM Convention) adopted on 13 February 2004 entered into force on 08 September 2016. The requirements are given below:

The ballast water of ships carries plants and animals which frequently settle in foreign sea regions, representing a danger for the indigenous flora and fauna with the potential to cause great ecological and economic damage. An approved “Ballast Water Management Plan” will regulate the procedures for preventing the exchange of marine organism. The necessary measures will involve exchanging the ballast water on the high seas and, in future, treatment of the ballast water by heating, filtration or even chemical process. The International Convention for the Control and Management of Ship’s Ballast and Sediments (BWM Convention) adopted on 13 February 2004 entered into force on 08 September 2016. The requirements are given below:

By 08 September 2017, all ships (i.e. vessels of any type operating in the aquatic environment, including submersibles, floating craft, floating platforms, floating storage units (FSUs) and floating production, storage and off-loading (FPSO) units will be required to:

• Have an approved ballast water management plan on board;

• Maintain a ballast water record book;

• Maintain their ballast water every voyage by performing ballast water exchange or by treating it using an approved ballast water treatment system; and

• Undertake an initial survey and be issued with an International Ballast Water Management Certificate for ships 400 gt and above to which the Convention applies, excluding floating platforms, FSUs and FPSOs;

• Ships registered in states that are not yet parties to the Convention will need to demonstrate compliance and may wish to undergo survey to obtain a Certificate of Compliance.

At a later date, ships will also be required to:

• Manage their ballast water on every voyage by treating it using an approved ballast water treatment system.

The compliance schedule for when ships will be required to install and use a treatment system is as follows:

New ships: Compliance on delivery for ships constructed on or after entry into force;

Existing ships: Compliance by first IOPP renewal survey on or after entry into force.

A treatment system is required to be fitted to vessels that carry out an IOPP renewal survey on or after 08 September 2017. The IOPP renewal survey refers to the one associated with IOPP Certificate under MARPOL Annex I.

The Convention does not normally apply to:

• Ships not carrying ballast water;

• Ships operating in domestic waters;

• Ships that operate under jurisdiction of a Party and on high seas (not making international voyages);

• War ships, naval auxillary or other ships owned and operated by the State. However, states are encouraged to adopt appropriate measures to ensure that ships act in a manner consistent with the Convention; or

• Permanent ballast carried in sealed tanks that are not subject to discharge.

Additionally under certain circumstances, Administration may issue exemptions to:

• Ships engaged on occasional or one-off voyage between specified ports or locations;

• Ships that operate exclusively between specific ports or locations (mutual consent).

92. Maritime Labour Convention (MLC) 2006:

This Convention consolidates and replaces all maritime related ILO Conventions except Seafarers Identity Document Convention. When in force, it will require every ship of 500 GT and over (engaged in international trade) to be certified in accordance with the provisions of the Convention. There shall be a Maritime Labour Certificate valid for five years with an intermediate endorsement between the second and third anniversary of the certificate. There shall be also a Declaration of Maritime Labour Compliance to accompany the certificate. The company will draw up this document for approval of the administration to show the national requirements implementing the convention and setting out the measures adopted by the company for their compliance.