Image Credit: Marinelink

Survey:

Authorised independent examination, investigation, and inspection, measuring or testing of ship structure, machinery and equipment, done and supervised by Surveyors appointed by regulatory or commercial organisations.

Classification Societies:

They are third party independent bodies e.g. ABS (American Bureau of Shipping), BV (Bureau Veritas), LR (Lloyd’s Register), ClassNK (Nippon Kaiji Kyokai), DNV (Det Norske Veritas), GL (Germanischer Lloyd).

Their functions:

1. To ensure that ship is soundly constructed and the standard of construction is maintained.

2. Carried out Statutory Survey on behalf of the Administration regarding the ship safety and prevention of pollution of marine environment.

Classed ship:

- A ship, which is built in standard and maintained under rules and regulations of Classification

- For a ship to be entitled to a class, Classification Society issues a Classification Certificate after carrying out Classification Surveys.

- Classification Certificate confirms that the ship has both structural and mechanical fitness for their intended services.

Maintaining the class:

To maintain a ship in the class:

– The owner must carry out regular surveys of hull, machinery and equipment.

– Carry out repairs necessary from time to time, under the supervision of Class Surveyors.

Statutory Survey:

– Carried out by Administration regarding the safety of the ship, sea worthiness and pollution, in accordance with national and international rules.

– Issued a certificate, this is essential to the ship’s ability to trade.

– If Statutory Survey is not certified, the ship can be detained.

Statutory Surveys are:

- International tonnage survey

- International load line survey 5 years interval

- Cargo ship safety construction survey 5 years –

- Cargo ship safety equipment survey 2 years –

- Cargo ship safety radio survey 1 year –

- Marpol IOPP & IAPP survey 5 years –

Classification Survey:

- Carried out by Classification Surveyor, to ensure that the ship has both structural and mechanical fitness, for intended voyage, in accordance with the class requirements.

- A classification survey is a visual examination that normally consists of:

– an overall examination of the items identified in the Rules for survey;

– detailed checks of selected parts, on a sampling basis;

– witnessing tests, measurements and trials where applicable.

Difference bet: Statutory Survey and Classification Survey:

- Statutory surveys are not assessing or measuring something for a client.

- Statutory survey will inspect something against a set standard or law.

- On completion of this survey, the ship is issued with a certificate, which is essential to the ship’s ability to trade.

- Class cannot go to the ship unless requested by the owner, or unless the ship is detained by the Port State Control.

Why Classification Societies sometimes issue the Statutory Certificate?

- Sometimes Administration delegates the authority, to the Classification Society to inspect and issue Certificates, on their behalf, regarding statutory requirements.

Port State Control:

1. Port State Inspection is a particular form of Statutory Survey.

2. Intention of Survey is to check that, ships flying the Flags of States comply with the Requirements of the Conventions.

3. When these ships are in Ports of States, Port State Authority has control over the ships in port, and has rights to inspect the followings, in order to avoid Substandard Ships:

– Safety Equipment.

– IOPP & IAPP Certificate.

– Oil Record Book.

– Sewage Treatment Plant.

– MARPOL Equipment.

For PSC purposes, Port Authorities will apply in general, the following Instruments.

ILL 66, SOLAS 74, MARPOL 73/78, STCW 78, COLARG 72 and ILO 76.

4. A Surveyor representing the Authority of the Government carries out the Port State Inspection.

Preparation for Port State Control Inspection: [As a CE]

- IOPP, IAPP, IEE Certificates for MARPOL

- Load Line Certificate

- SOLAS Certificates

- STCW Certificates, kept ready.

- Safety Equipment prepared for testing and inspection.

- MARPOL Equipment prepared for testing and inspection, such as:

– OWS operation and alarm test.

– Incinerator tested and kept ready for demonstration, and alarm test.

– Sewage Treatment Plant, in good order, and dose chemicals.

– Tank top near OWS and Bilge Pumping Station kept clean.

– Bilge overboard discharge valve, tightly closed and kept under lock and key.

– Update and attach ORB, with photocopies of MARPOL Certificates, original Oil Disposal Receipts, and Dirty Oil and Sludge Piping Diagram.

Flag State control:

1. Flag State or Administration has responsibilities that the ships built to their flag, comply with the Requirements of the Conventions, in construction and upkeep afterwards.

2. Government body carried out Surveys and issued Certificates relating to safety of the ship, sea worthiness and pollution.

3. Flag State Control is limited to ensure that valid Certificates are onboard:

- Passenger ship safety certificate Validity 1 year.

- Cargo ship safety construction certificate 5 years

- Cargo ship safety equipment certificate 2 years

- Cargo ship safety radio certificate 1 year

- International load line certificate 5 years

- MARPOL IOPP & IAPP certificate 5 years

- International sewage pollution prevention certificate (ISPP) 5 year.

Preparation for Entering a Stringent Port:

- In Port State Control system, inspections are done at the port, in order to avoid Substandard Ships.

- For PSC purposes, Port Authorities will apply in general the following Instruments.

1. International Convention of Load Line. ILL 66

2. International Convention for Safety of Life at Sea. SOLAS 1974.

3. International Convention for the Prevention of Pollution from Ships.

MARPOL 1973/78

4. International Convention on Standard of Training,

Certification and Watch Keeping for Seafarers. STCW 1978.

5. Convention or the International Regulation for Prevention of Collision at Sea.

COLARG 72

6. Merchant Shipping (minimum standard) Convention. ILO 1976

Before entering the port, prepare the following in general:

1. Certificates and Documents prepared.

2. ORB properly entered and updated.

3. Sludge formation should be compared with 1% of voyage fuel consumption.

4. Receipt for sludge and waste oil disposal to shore facility, attached to ORB.

5. ORBs retained for 3 years after date of last entry should be onboard.

6. IOPP Certificate has validity.

7. OWS alarm tested, discharge valve closed, spare filter onboard, tank top near OWS cleaned.

8. ODM tested for 15ppm alarm, and automatic stopping device.

9. USCG Notice posted especially near OWS and bilge pumping station.

10. Boiler not to emit black smoke.

11. Incinerator prepared for demonstration:

- Waste oil tank, drained-off water and heated up to 80 – 90˙C.

- Photocell, pilot burner and waste oil burner of incinerator removed and cleaned.

- Flame failure, high flue gases temperature, and force draught fan failure alarms tested.

- Line filter for waste oil line, cleaned.

- Incinerated ash collected to show to Surveyor, or if disposed to shore facility, receipt attached to ORB.

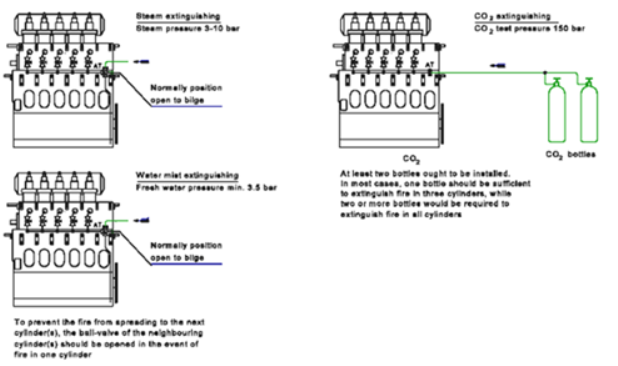

12. Fire extinguishers and fire detection system, CO₂ alarms system, tested.

13. Check Sewage plant.

Periodical Survey: Mainly consists of Annual Survey and Special Survey.

Annual Survey (machinery):

- General Inspection of conditions of the whole machinery and equipment.

- At each Annual Survey between Special Surveys, main and auxiliary machinery are generally examined, and placed in satisfactory running condition.

- If necessary, some of the machinery or parts are to be opened-up for the surveyor to examine.

- Survey items include steering arrangement, windlass, weather decks, watertight bulkheads, doors, fire equipment, hatch ways, etc: (hull survey items).

Special Surveys (machinery):

- Thorough Inspection of the whole machinery and equipment

- Including open-up inspection of machinery and equipment, their performance tests and inspection of electrical installation.

- Main and auxiliary machinery are subjected to Special Survey, at intervals similar to those for special surveys of the hull, i.e. every 4 years, in order that both may be recorded approximately at the same time at each Special Survey.

1. All openings to sea, including sanitary and all overboard discharges together with cocks and valves to be examined internally and externally.

2. Fastenings to the shell plating are to be renewed, if surveyor recommends.

3. Pumps and pumping systems including valves, cocks, pipes and strainers are to be examined.

4. Shafts, except propeller shaft, bearings and line shafts to be examined.

5. Foundations of main and auxiliary machinery to be examined.

6. Cylinders, cylinder heads, valves and gears, fuel pumps, scavenging pumps, superchargers, pistons, crossheads, connecting rods, crankshaft, clutch, reversing gears, air compressors, intercoolers, and such other items covered by CMS system.

CMS/ CSM:

- A Special Survey carried out on a planned schedule, within a circle of 5 years, at the request of the owner, and upon approval of the proposed arrangement

- Approximately 20% of the surveyable machinery items shall be examined each year.

- Completion of circle implies that all essential machinery parts have been examined within a previous 5 years.

Items covered by CMS:

1. Main propulsion machinery, steam turbine.

2. Power transmission and main shafting.

3. Auxiliary engine.

4. Air compressors, air receiver and blowers.

5. CW, FO, LO, feed water, condensate, bilge, ballast and fire pumps, etc:

6. Condenser and feed water heaters, coolers, oil heaters, and evaporators.

7. Fuel tanks (more than 1 m³), cargo oil pumping installation.

8. Deck machinery.

9. Steering gear including operational test and checking of relief valve setting.

10. Reduction gears; to check the gear teeth, pinions, etc.

11. Other items of machinery and equipment, which the Society considers to be covered by CMS.

Items not covered by CSM:

1. Propeller and shaft.

2. Sea valves below load water line.

3. Boiler, EGE.

4. Cargo handling gears

5. Measurement of crank shaft deflections for ME.

6. Measurement of clearance at the aft end of stern tube.

7. Items of machinery and equipment which are not required open-up inspection at Periodical Surveys, e.g. foundation bolts, refer installation, electrical installation, incinerators, etc.

8. Performance tests, pressure tests required at Periodical Surveys.

9. Machinery and equipment of small capacity or low frequency operation, e.g. emergency air compressor, hand pump for bilge, FO tanks less than 1 m3

10. Machinery and equipment of special type or newly developed type.

11. Other items which the society considers not to be included in CMS system.

Planned Maintenance:

Planned maintenance should be flexible, and following items should be considered.

1. Weather Condition.

2. Length of voyage, trade.

3. Maintenance of Safety Equipment, and Emergency Team Training.

4. Optimum conditions for Statutory and Classification Surveys.

5. Dry Docking.

6. Manufacturer’s advises.

7. Breakdown maintenance.

8. Replacing of spares.

9. Controlling and recording of maintenance up-to-date.

Planned Maintenance should include:

1. Short term maintenance, weekly, fortnightly, and monthly.

2. Long term maintenance, 3 monthly, 6 monthly, yearly.

3. Operational maintenance, to be carried out if necessary.

Construction of a Planed Maintenance Schedule:

1. Plan must be flexible, so that changes, orders, or cargoes do not upset it unduly.

2. Adaptable to various weather conditions.

3. Length of voyage, routes and trades, that vessel is involved must be considered.

4. Maintenance of Safety Equipment and Emergency Team Training should be integrated with overall maintenance plan.

5. Appropriate equipment is brought-up to optimum condition for Statutory and Class Surveys, such as ‘Safety Equipment’, ‘Load Line’, and ‘Lifting Apparatus’.

6. Dry-docking and repair period should be integrated with the plan.

7. Manufacturer’s advises, to be complied with, and all Manufacturer’s Maintenance Logs to be completed.

8. Plan should include availability of appropriate equipment, for breakdown maintenance, due to unforeseen circumstances.

9. Provisions made for spare part replacements for wear and tear maintenance.

10. Plan must be carefully thought-out, well controlled, and efficient recording system must be kept up-to-date.

Classification Surveys:

– Annual Survey of hull and machinery.

– Special Survey of hull and machinery: the first special survey becomes due 4 years after the date of built. Special Survey can be extended up to 5 years if not completed at one time. [S/S 4+1 year.]

– Continuous Survey or running survey of hull and machinery.

Automation Survey :

Carried-out at 1 year from the date of installations and periodical Special Surveys are to be carried out at 4 years intervals. ( 1 + 4 )

At 1 year from the date of installation, during this Survey:

1. General examination of automatic and control system.

2. Examination of ship service generator in operation and control system.

3. Random checking of function indicators, alarms and control actuators.

4. Examination of machinery records to ensure that the performance of the control system are in good order through the period since last survey.

5. Machinery space fire detection and bilge alarms.

At interval of 4 years, during this Special Survey:

1. All requirements of Annual Survey are done.

2. Examination of control actuator,

3. Insulation resistance of all electrical equipment and circuits.

4. Control system of UMS for proper operation.

5. Automatic alarms and safety systems.

Tail shaft Survey:

- Tail shaft with water lubricated bearing, to be drawn and surveyed, every 3 years for single screw, and every 4 years for twin screw.

- Tail shaft with oil lubricated bearings, to be drawn and surveyed once every 4 years.

- It is a survey done by Surveyor at the request of owner or his agent, due to damage of hull, machinery or equipment, which can effect the seaworthiness, or class of ship.

- All necessary repairs to be carried out to Surveyor’s satisfaction.

Tail shaft Survey includes:

1. Complete withdrawal of tail shaft.

2. Propeller nut and tail shaft threaded end to be checked.

3. Cone, key and keyway to be checked, and forward part of the taper to be checked for crack with approved crack detecting method.

4. Tail shaft bearing wear, to be checked.

5. Stern bush and bearings, to be checked.

6. Shaft sealing arrangement, including oil system, to be checked.

Boiler Survey:

The Class Surveyor shall survey every boiler of working pressure 3.5 bar and heating surface area 4.65 m² and above.

Survey interval:

DNV & LLOYDS: Every 2-years interval until 8 years old, and every 1-year interval after 8 years old.

GL: Every 2½ years interval until 10 years old and every 1-year interval after 10 years old.

Annual Boiler Survey includes:

1. Hydraulic testing ( 1.25 x approved working pressure for not more than 10 minutes ).

2. Pressure testing of main steam piping at 15% in excess of approved working pressure for not more than 10 minutes.

3. Internal inspection, hammer test to furnace, stays bolts, fire and stay tubes, brickwork, baffles and casing.

4. Inspection of alarm and control system, fuel system, feed system, all steam piping and lagging arrangement, foundation and chocking system.

5. Checking of pressure gauge and water level gauges.

6. Testing of safety valves to blow off at the pressure not greater than 3% above w.p.

7. After 10 years old or at any time, if surveyor demands, drill test near the water line should be done to determine actual thickness of boiler shell. If found necessary, lower working pressure may be reassigned

At 4 years interval :

In addition to above Annual inspection procedure, all valves on boiler required to open-up and inspected, every 4 years at the time of Annual Survey, or at the next regular dry docking period thereafter.

Preparation for survey:

1. Clean water and fire sides.

2. Gags or clamps must be prepared for safety valves.

3. Boiler must be filled with water at a temperature not more than 38˙C for fire tube boiler and not more than 82˙C for water tube boiler.

4. Drip pan placed under all burners.

5. Tank top and bilges cleaned.

6. Pump for pressure test to be kept ready.

7. Blanks must be installed at steam valves and water level gauge.

Damage Survey:

1. It has to do with causalities and accidents, repairs, causes and remedies.

2. Damage to hull, machinery and equipment, which effects seaworthiness or classification, is to be submitted by owner and representative, for examination by Surveyor.

3. All repairs to be carried out to surveyor’s satisfaction.

When damage occurs:

If the vessel is classed, and the port has facilities of Classification Society, and Underwriter Surveyors and repairs firm:

1. Invite Classification Surveyor

2. Invite Underwriter Surveyor (appointed by Insurers)

3. Both Surveyors to survey the damage

4. Repairs to be carried out as per Class Requirements.

5. Quotation of repairer and repair cost to be submitted to Underwriter Surveyor to negotiate any reduction that may appears necessary.

6. Both Surveyors to survey the repairs when completed.

7. Repair bills must be endorsed by the Underwriter Surveyor so as to claim insurance.

8. Underwriter Surveyor does not accept bills for transportation.

9. Class Surveyor must confirm class of machinery (Interim Certificate of Class)

10. Log Abstracts and damage reports must be submitted to the Class Surveyor and owner.

If the vessel is classed, but the port is very small, and duly appointed Surveyor may not be available:

1. Call the next best surveyor.

2. If no surveyor is available, Damage Survey may be carried out by two Chief Engineers of same Flag (Port of Registry), but should not be from same company, to avoid biased report.

Actions taken by C/E when ME breakdown, fire / explosion occurred:

1. Find out extent of damage or breakdown.

2. Find out whether the damage can be repaired or not by ship crew.

3. Consider that vessel can resume the voyage or not.

4. Inform present situation to HO and take instruction.

5. Record exact times and position of ship.

6. Take pictures of damage for evidence.

7. After temporary or proper repair, resume voyage under suitable speed.

8. Prepare detail damage report and submit to head office.

CE damage report form:

1. Date, time, approximate ship position, voyage no.

2. Where damage occurs.

3. Causes and extent of damage.

4. HO confirmation and approval for major repair.

5. Actions taken.

6. Repaired condition, detail statement of clearances, measurements, etc.

7. Used and required spares to be ordered.

8. Training and instructions to prevent reoccurrence.

9. Take photos before and after repairs.

Insurance:

Ship owners insured their ships against unforeseen damage or loss such as:

- Actual Total Loss.

- Constructive Total Loss (the cost of repair being greater than the value).

- Presumed Total Loss.

- Partial Loss.

- Third party Liabilities (collision, injury to crew)

The rate of Insurance:

It depends on size, age and engine, and a vessel with valid Certificates of Classification is likely to attract more favourable rate than a vessel without.

Insurance claim purpose:

Following items are necessary:

1. C/E damage report

2. Log abstracts.

3. Damage report form for insurance claim.

4. Class Surveyor recommendation.

5. Repair bills endorsed by Underwriter Surveyor.

Protecting and Indemnity Association:

- This is a P&I Club or Mutual Insurance Club or Small Damage Club.

- An association formed by Ship Owners, having certain risks to insure.

- That certain risks are not covered by the Insurance Policy.

- A Mutual Insurance Company, belonging to ship owners, which insures the damages relative to the ship, which are not covered by Insurance Policy.

Protecting:

1. Loss of life and personal injury.

2. Hospital, medical and funeral expanses arising from injury claim.

3. Sickness and repatriation.

4. Cargo damage due to improper navigation.

5. Oil pollution.

6. Collision damage, etc.

Indemnity:

1. Claim in respect of wrong delivery of cargo.

2. Ship’s liability to cargo, after collision, not covered by policy.

3. Fine or penalty imposed as a result of custom law, health regulations, and immigration law including smuggling.

Interim Certificate of Class:

- Class Surveyor will issue the Certificate, when repairs have been completed to the Surveyor’s satisfaction.

- This Certificate enables the vessel to remain in class, until the next full survey due.

- Validity is until next survey due.

Certificate of Seaworthiness:

- To enable to proceed to the next port, the Surveyor other than Class Surveyor issues it.

- If the Classification Surveyor does not carry out the survey, the requisite certificate that is issued will be one of seaworthiness.

- This Certificate enables the vessel to proceed to her next port, where a further survey by the Classification Surveyor will be conducted, so that Interim Certificate of Class can be issued.

Seaworthiness:

1. The fitness of the vessel in all respects for carrying cargo and crew in safe condition.

2. Important items concerned are stability, strength, freeboard, machinery and design, and they must be entirely satisfactory.

Franchise Clauses:

- These state certain portion of insured value, for which Insurers are not liable to pay.

- There are two kinds of franchises:

[These state the percentage of the claim, which the Assured must bear.]

Deductible:

1. If amount of loss does not exceed the franchise amount the Insurers (Underwriters) are not liable to pay at all.

2. But if the amount of loss exceeds the franchise amount Insurers are liable to pay that portion which exceeds the franchise amount.

[Only claims in excess of certain percentages are paid, i.e. the Assured pays the first so much

percentage of any claim.]

Non-Deductible:

1. If amount of loss does not exceed the franchise amount the Insurers (Underwriters) are not liable to pay at all.

2. But if the amount of loss exceeds the franchise amount Insurers are liable to pay the whole amount.

[The Underwriter pays the whole claim if it exceeds the stipulated percentage.]

Load Line Survey:

1. Carried out as first Survey when a new ship is completed.

2. During this survey freeboard arrangement and conditions of assignment, are made in accordance with International Regulations and Documentation.

3. After thorough inspection, Load Line Certificate is issued, and its validity is 5 years, subjected to Annual Survey.

4. Load Line Renewal Survey held at 5 years interval from the date of build, and whenever a periodical Special Survey is made.

5. Validity of Load Line Certificate extends to the end of next Special Survey.

6. During this survey, all freeboard items to be examined, and load line markings to be verified. [With trammel gauge]

7. On satisfactory completion of the Survey, an International Load Line Certificate, valid for 5 years is issued.

8. Load Line Annual Inspection carried out within 3 months ± anniversary date of the Certificate.

9. Main purpose of Load Line Survey is, to examine that the ship construction complies with Requirements of Convention.

Requirements can be grouped into 4 categories:

1. Structural Strength.

2. Watertight Integrity.

3. Stability.

4. Crew Quarter Protection.

Conditions of Freeboard Assignment: Why it is important?

1. Efficient means of protection must be provided for all openings to hull and superstructure, for protection of crew in heavy weather, and for rapid freeing of water from weather deck.

2. Condition of Assignment must be maintained, at all times in satisfactory condition.

3. Annual Inspection to be made by assigning authorities, to ensure that they have been maintained in satisfactory condition for continued validity of Load Line Certificate.

Preparation for Load Line / Annual Survey:

Ship Officers/Engineers should ensure, the following items are in efficient condition, prior to the Classification Society Surveyor’s arrival on board.

1. Load line marks, verified with existing Load line Certificate.

2. Coamings and closing appliances of exposed hatchways, hatchways within superstructures, to be examined.

3. Holding-down clips/bolts are in good order; packing and seats are watertight.

4. Watertight steel hatch covers are to be hose-tested (pressure not less than 2 kg/cm² from a distance of 1.5m with ½ ” bore jet) for water-tightness.

5. Spring-loaded battening-down wedges between covers, and holding down cleats, to be in good working condition.

6. Exposed engine casing and their openings, fiddley openings, ER skylights and their closing appliances, to be checked and tested. ER skylight to be able to close from remote position.

7. Test Ventilators, check all flap levers are free, and locking pins are in place and secured by chain to ventilation casing.

8. Check air pipes and their closing means, flame traps for fuel oil tank’s air pipes, are in order.

9. Watertight doors and closing arrangements to be checked.

10. Scuppers and their discharge pipe and valves below the freeboard deck, checked for corrosion/wastage.

11. Gangways and cargo ports below freeboard or superstructure deck, to be checked.

12. General condition of hull, as far as could be seen.

Load Line Certificate:

- A Certificate issued to a ship, if she is built and maintained thereafter, according to the requirements of International Convention on Load Line (1966)

- Issued by the Administration or Classification Society.

- Validity is 5-years and subjected to Annual Survey.

FO DB Tank Survey:

Transferring, cleaning and gas freeing must be done.

Testing of atmosphere:

˗ Toxicity

˗ O₂ content with Oxygen Analyser

˗ Explosive Gases with Explosimeter

˗ Gas free certificate from Chemist.

Survey:

1. Heating coil leak test: [1.5 times working pressure.]

2. Condition and testing of level alarm

3. Condition of sounding pipe, striker plate and flame trap

4. High temp. alarm sensor

5. Internal inspection by surveyor.

Sounding pipe requirements:

1. Used to determine the dept of liquid in a tank.

2. Should be as straight as possible.

3. If it is not possible, pipe curvature should allow easy passage of sounding rod or chain.

4. Normally, bore of pipe must be not less than 32mm.

5. Striking pad of adequate size and thickness placed under the pipe.

IOPP Certificate:

Issued after Survey is carried out by Administration, in accordance with International Convention for Oil Pollution Prevention. Validity is 5 years.

Checking procedure for IOPP Certificate, When CE sign-on:

1. Check the validity of certificate.

2. Check the ORB up to date recording.

3. Visual inspection of plants in good order.

4. Check 15-ppm alarm and automatic stopping device.

5. Check spare filter element, at least one no.

6. Waste oil tank and capacity.

7. Compare fuel consumption and sludge formation.

8. Incinerator capacity and workability.

IOPP Survey preparations:

1. Validity of the IOPP Certificate checked.

2. Proper entry of ORB and, sludge disposal receipts to shore facilities attached to ORB.

3. Calculate the sludge formation, and compared with 1% of voyage fuel consumption.

4. Incinerating time, incinerated waste oil amount, remainder of waste oil in waste oil tank should be reasonable.

5. Incinerator kept ready for demonstration, such as heating of waste oil tank, alarms, control and functional test, done prior to survey.

6. OWS in good order, its piping free from oil leaks, overboard valve from OWS locked in closed position. If possible, one section of discharge pipe removed and free from oil residues.

7. ODM checked for 15-ppm alarm and automatic stopping.

8. High level alarms of sludge tank, waste oil tank and bilge holding tank checked.

9. Spare filter for OWS must be onboard.

10. USCG Notice posted near OWS and bilge pumping out station

Survey by CE:

Requirements:

- CE must have first class competency certificate or equivalent.

- At least 3 years service as CE on owner’s vessels.

- Should be at sea or in port with no Class Surveyor.

- Generally cannot survey on Safety Equipment, pressure vessels, and main engine except in unit overhaul.

- Can survey auxiliary machinery such as, AE, pumps, and Air Compressors.

- DNV allows half of all items covered by CMS, of which there are more than one, may be surveyed by CE.

Confirmatory Survey:

1. When any machinery and equipment, allowed to be surveyed by CE, were opened-up and examined by CE at sea, Confirmatory Survey of these items must be done by the Class Surveyor at next port of call, or the first port of opportunity.

2. During this survey, show the followings to Class Surveyor:

a) Relevant entries in log book.

b) Two copies of statement, signed by CE.

c) Description of items surveyed by CE.

d) Spare parts replaced.

e) All photos for evidence.

3. If the surveyor does not satisfied, he has right to open up the item for inspection. If he satisfy, he will issue Interim Certificate of Class.

AE survey by CE:

Safe operation of propulsion must not be effected, when CE surveys AE.

1. All cylinder covers, valve gears, pistons, piston rings, liners, top and bottom end bearings, all upper half of main bearings, gudgeon pins are to be opened up.

2. To withdraw at least two bottom half bearings for inspection.

3. Checking of all crank pin bearings, journals and gudgeon pins.

4. Cylinder liner gauging and recording.

5. L.O. cooler to be opened up for inspection.

6. Defective attached pumps such as LO pump, FW pump, etc. to be opened up.

7. Testing of all safety devices, alarm and trip.

8. Crankshaft deflection taken and recorded after reassembled.

Confirmatory survey by Class Surveyor:

» He has rights to open up at least two main bearings and two bottom end bearings, and crankshaft deflections to be taken and checked with CE records.

» Run the engine and load-tested. All safety devices tested for alarms and trip for generator and switchboard, and are to be witnessed by the surveyor. (DNV).

Generator load test:

1. After priming the AE, start and run under no load, low speed condition for about 3 to 5 min.

2. Then stop and checked externally for overheating. If no overheating, crankcase doors to be opened and checked temperature of bearings and running gears.

3. If satisfactory, restart the engine at full speed, no load condition for about 30 min., then stopped and recheck again.

4. If satisfactory, restart and load-shared with running generator engine. Load sharing should be gradually increased in small steps, taking about 6 to 10 hours to reach at full load condition. While running in full load, another generator to be run in stand-by for possible emergency use. Synchronising or load sharing steps: 25%, 50%, 75%, and 100% within 6 to 10 hrs.

5. All necessary items checked, during load increasing steps.

6. Then peak pressure indicator and other performance data, taken for each cylinder and compare with test results.

7. Load test should be done, until preferential trip initiates.

A/E Damage Insurance Claim:

Items necessary to submit to Superintendent Engineer are:

» CE damage report.

» Log abstracts.

» Damage report form for insurance claim.

» Class surveyor recommendation.

» Repair bills endorsed by Underwriter Surveyor.

If A/E damage occurred at sea:

1. Date, time, position, voyage no., where the damage occurred, extent of damage, causes of damage, are reported to Head Office in detail.

2. Take HO confirmation and approval for major repair.

3. Take required damage photos.

4. When at nearest port, repair condition, photos before and after repair are submitted to Surveyor for Confirmatory Survey.

5. If Surveyor does not satisfy, he has right to open-up for inspection.

6. If Surveyor is satisfied, he will issue Interim Certificate of Class, and give recommendation.

If A/E damage occurred in Port:

1. Invite Class and Underwriter Surveyors through Master or Agent to make surveys.

2. Negotiate with shipyard repair firm, about cost and prices.

3. After completion of shipyard repair firm’s work, Surveyor will inspect the AE, and issue Interim Certificate of Class, and Underwriter Surveyor will inspect and give repair cost and certified endorsement.

4. Repaired condition with photos, and used spares, reported to HO and required spares ordered.

Surveys, requested by owners, charterers, underwriters and authorities:

1. Damage Survey

2. On and Off Hire Survey

3. Lay-up Survey

4. IMCO Survey (Inter-governmental Maritime Consultative Organisation.)

5. Pre-loading Survey

6. Draught Survey

7. Ullage Survey

8. Conditional Survey: [the ships over 15 years of age may be subjected to survey, annually, so as to ensure their seaworthiness, only upon request by owners and underwriters.]

On and Off Hire Survey:

1. The most time-consuming survey and must be done in daylight, with the hatches fully open, empty and clean.

2. Two Surveyors will have to carry out this Survey.

3. One representing the owner, may be the Master, and the other representing the Charterers.

The areas of Survey include:

1. Portside Bulwark/rails and Deck. [Bulwark is the part of ship’s side, above Upper Deck.]

2. Starboard side Bulwark/rails and Deck.

3. Deck houses and cargo gears.

4. Hatch coamings and hatches.

5. Shipsides, Tank tops, Bulkheads fore and aft.

6. Bunker Survey.

In Water Survey:

1. Due to increasing in size of oil tankers and bulk carriers and consequently, small numbers and size of docks incapable of docking these vessels, In Water Survey is permitted by Class.

2. This survey includes visual examination of hull, rudder, propeller, sea inlets and measuring the wearing of rudder bearings and cleaning of hull by suitable methods.

Limitation:

1. Not periodical special survey.

2. For less than 10 years old of vessels.

3. Must have Class notation to suit for in water survey.

4. Hull painted with high resistance paint and fitted with impressed current system for hull protection.

5. Class must approve Diver Firms.

6. Ship draught not more than 10 meters.

Requirements:

1. Hand held closed circuit TV camera that can be controlled remotely from surface monitoring system.

2. Communication between Diver Party and Surveyor.

3. Water is clean and clear.

4. Carried out in daylight.

Docking Survey:

1. The ship must be examined in dry dock preferably at 1-year intervals, but new Class Regulations allowed intervals of up to 2 years.

2. The vessel is to be placed in dry dock or upon a slip way and the keel, stern frame post, rudder and outside plating, propeller, exposed part of stern bearing assembly, rudder pintle and gudgeon securing arrangements, sea chest, strainers and other fastenings are to be cleaned and examined.

3. The stern bearing clearance and rudder bearing clearance are to be ascertained.

Underwater [Bottom] Survey on Dry Dock:

1. Shell plating washed and brushed down, checked for distortion, bulging, roughness and corrosion.

2. Welding seams inspected for cracks.

3. Zinc anodes checked for replacement.

4. Shipside valves and cocks removed, overhauled and refitted.

5. Shell box or Sea Chest wire brushed and applied anti-fouling paint.

6. Remove drain plug of rudder to determine the present of water.

7. Measure wear down of rudder and jumping clearance.

8. Bearing metal of gudgeon pin of rudder checked and clearance

must not exceed 6 mm.

9. Pintle nuts with locking device checked.

10. Propeller carefully examined especially near the tip on the driving face and fore side for cavitation. Damaged propeller blades repaired.

11. Wear down of tail shaft measured. For oil lubricated: 2 x original clearance.

For water lubricated: maximum 10 mm.

12. Stern tube checked for tightness.

13. For CPP, checked for good working order.

14. Anchor and chain cable, lay up and measured.

Dry Docking:

Required Plans and Arrangements for Docking:

1. Docking plan.

2. General arrangement plan.

3. Capacity plan.

4. Shell expansion plan.

5. Shell painting area plan.

6. Mid ship section plan.

7. Longitudinal section plan.

8. Anode plan.

9. Shafting and propeller arrangement.

10. Rudder, to check.

Docking plan:

▭ Provides the positions of frame spacing, watertight bulkheads, docking plugs, etc.

▭ Determine the positioning of keel blocks, bilge blocks, bilge shore, breast shore

when the ship is on dock.

Preparation for Dry Docking: [As a CE.]

1. Take all information from HO and dockyard.

2. Sent Docking Plan to Dockyard.

3. Prepare dockyard and ship staff repair lists and survey items.

4. Prepare necessary spares and store, drawings, Manuals, Certificates, special tools and measuring equipment.

5. 2/E should be instructed to perform the followings:

a) Label all sea valves, all shipside valves and cocks. Mark the positions of items to be repaired, with tags or colour code.

b) Keep Emergency Fire Pump, Emergency Generator, Air Compressors, Emergency Air Bottle, and portable Fire Extinguishers in good order.

c) Lock Fixed Fire Fighting Installation, as per shipyard rules.

d) Shut down Boiler, OWS, Sewage Plant if dockyard does not allow.

e) Lock overboard discharge valve in closed position.

f) Fill up Settling and Service Tanks.

g) Press up Air Bottles and Emergency Air Bottle, and shut the valves tightly.

h) ME crankshaft deflections to be taken and recorded.

i) Hose down tank tops, and empty Bilge Holding Tank, Sludge Tank, Waste Oil Tank.

j) Prepare for receiving of Shore Power Supply, International Shore Connection, cooling arrangement for Air Conditioning and Provision Plants.

k) Provide fire watch in ER at all times, and follow Dockyard Fire and Safety Regulations.

l) Adjust required trim and draught, with deck officer.

m) Take soundings of DB tanks and cofferdam.

During Docking:

1. Discuss with the superintendent and dockyard repair manager about repair jobs.

2. Assist Surveyor and record the survey items.

3. Witness all alignment works and clearance measurements.

4. Take and record propeller shaft wear down, rudder wear down and jumping clearance.

5. Check oil tightness of stern tube.

6. Check all completed underwater jobs, done by dockyard.

7. Check all sea valves, shipside valves and cocks, after overhauling.

8. Check all repaired jobs done by ship staff, and used spares and store.

9. Make daily records.

Undocking:

1. Check all repair and underwater jobs in accordance with repair list.

2. Check all measurement data are correct and completed.

3. Make price negotiation.

4. When sea water level covers the sea chest, each sea valve should be opened and checked for any leakage.

5. Purge air from cooling seawater pumps, run the pumps and check pressure.

6. Test run the ship generators, until satisfactory, and cut out shore supply, cut in ship generator, disconnect the shore connection, restart seawater pump, record the time and read watt meter.

7. All sea valves, shipside valves, repaired pipes, repaired jobs must be finally checked, before leaving the dock.

8. Prepared for ME.

9. All DB tank soundings checked.

After Leaving the Dock.

1. Checked ME crankshaft deflection and compare with former record.

2. Prepare for Docking Report.

Cargo ship Safety Construction Certificate:

- Issued after survey to every cargo ship of 500 GRT and over, by the government of Flag State.

- Validity is 5 years, subjected to survey at specified intervals.

- During survey, following items must be in accordance with the requirements of SOLAS 1974 Convention.

1. Ship structure, including structural fire protection.

2. External examination of ship’s bottom.

3. Electrical installation.

4. Steering gear.

5. Pressure vessels and fitting.

6. Main and auxiliary machinery.

Cargo ship Safety Equipment Certificate:

- Issued after survey to every cargo ship of 500 GRT and above, by the government of flag state.

- Validity is 2 years and annual inspection of ± 3 months.

- Safety Equipment Survey, consists of inspection and demonstration:

1. Fire fighting appliance, FFA

2. Life saving appliance, LSA

3. Navigation equipment

4. Vessel documentation

5. Alarm system.

Concerning items for CE:

1. All portable and semi-portable fire extinguishers

2. Fixed installation of fire fighting

3. Fixed fire detection and alarm system

4. Fire man’s outfit

5. Emergency fire pump, main fire pump

6. Emergency stop switches, remote quick closing valves, skylight, watertight doors

7. Emergency generator and lighting system

8. Escape ways in ER.

9. Steering gear and communication system

10. Life boat engines and launching system.

11. All the items required by SOLAS must be prepared.

Some government administrators publish checklist for survey. This is an essential tool for preparing for a survey, so that one surveyor should be able to complete the survey in ½ day.

Safety Equipment Survey:

- Government body carried out at every 2-year interval, and annual inspection of its validity.

- At every port, where the ship called on, Government body concerned has a right to inspect Safety Equipment, IOPP Certificate, Sewage treatment plant, Marpol equipment, and ORB for Port State Control measures.

1. To inspect Fire hoses, Nozzles and container box.

2. Fireman’s outfits: Breathing apparatus.

3. All portable extinguishers.

4. Emergency and Main fire pumps.

5. Emergency generator.

6. Fixed installation [gas level, cleared lines and nozzles, operating mechanism and alarm system].

7. Audible Fire alarms, Fire detection system, Abandon ship warning, and Ship Siren and Muster list.

8. Stop switches outside ER, for fans, fuel pumps, fuel tank valves, Skylight doors, Watertight doors, Fire dampers.

9. Inert gas system of cargo ships, 500 tons Gross Tonnage and above.

10. Life raft Certificate.

11. Life buoys, Smoke floats, Buoyancy lines.

12. Lifeboat internally and externally.

13. Condition of Buoyancy tanks inside lifeboat.

14. Illuminating power sources, for launching of Lifeboat and Rafts

15. Latest Nautical Publications.

16. To run Lifeboat Engine, ahead and astern in water.

17. To swing out all lifeboats at least 50% lowered into the water.

18. To lower Davit span ropes and Boarding ladders.

19. To lay out and survey all lifeboat equipment.

20. To survey Life jackets.

21. To check Navigation lighting.

22. To check pilot ladder with lighting.

23. To inspect fall release mechanism [free fall or float free].

Certificates onboard:

1. Certificate of Registry

2. International Tonnage Certificate

3. International Load Line Certificate

4. International Load Line Exemption Certificate

5. Certificates for Master, Officers and Ratings

6. Derating or Derating Exemption Certificate

7. International Oil Pollution Prevention Certificate

8. International Sewage Pollution Prevention Certificate

9. International Safety Management Certificate, SMC

10. International Medical Certificate

11. Passenger Ship Safety Certificate

12. Cargo Ship Safety Construction Certificate, SAFCON

13. Cargo Ship Safety Equipment Certificate, SEC

14. Cargo Ship Safety Radio Certificate

15. Exemption Certificates for SAFCON, SEC and Radio Certificate

16. Certificate of Classification

17. Certificate of Insurance or other financial security

in respect of civil liability for oil pollution damage.

18. International Pollution Prevention Certificate

for the Carriage of Noxious Liquid Substances in Bulk. [NLS Certificate]

19. Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

(Chemical Tanker)

20. Certificate of Fitness for the Carriage of Liquefied Gases in Bulk

(Gas Carrier)

SOLAS Certificates:

- Passenger Ship Safety Certificate

- Cargo Ship Safety Construction Certificate

- Cargo Ship Safety Equipment Certificate

- Cargo Ship Safety Radio Certificate

- Cargo Ship Safety Certificate 1

- Exemption Certificate

- Document of Compliance with the special Requirements for Ships carrying Dangerous Goods

- Minimum Safe Manning Document

- Document of Authorization for the Carriage of Grain

- International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

- International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk

- International Certificate of Fitness for the Carriage of INF Cargo

- Safety Management Certificate (ISM)

- Document of Compliance (ISM)

- High Speed Craft Safety Certificate

- International Ship Security Certificate

MARPOL Certificates:

MARPOL Annex I:

1. International Oil Pollution Prevention Certificate (IOPP Certificate)

2. Statement of Compliance with CAS (as a supplement to ship’s IOPP Certificate)

MARPOL Annex II:

1. International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

2. Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

3. International Pollution Prevention Certificate for the Carriage of Noxious Liquid Substances in Bulk (NLS Certificate)

4. Certificate of Fitness for Offshore Support Vessels

MARPOL Annex IV:

1. International Sewage Pollution Prevention Certificate

2. Result of calculation of moderate rate of discharge in accordance with MEPC.157(55)

MARPOL Annex V:

1. Garbage Management Plan

2. Garbage Record Book

MARPOL Annex VI:

1. International Air Pollution Prevention Certificate

2. Engine International Air Pollution Prevention Certificate

incl. Technical File and Record Book of Engine Parameters if applicable.

3. International Energy Efficiency Certificate

Oil Record Book: Part I

- Operations involving oil and oily mixtures recorded in ORB.

- Dates, geographical position, quantity, tank identification, and duration of operation entered.

- Port State Authority may take copies of entries, and if so requested, the master is required to state that it is a true copy.

- ORB retained onboard for 3 years after date of last entry.

To be recorded:

1. Ballasting and cleaning of fuel oil tanks. (Code a.)

2. Discharge of dirty ballast or cleaning water from oil fuel tanks. ( b.)

3. Disposal of oil residues (sludge). ( c.)

4. Non-automatic discharge overboard or disposal otherwise, of bilge water accumulated in machinery spaces ( d.)

5. Automatic discharge overboard or disposal otherwise, of bilge water accumulated in machinery spaces ( e.) (e.g. transfer of bilge water to slop tank) (identify tank)

6. Conditions of ODM and Control System. ( f.)

7. Accidental or other exceptional discharge of oil. ( g.)

8. Bunkering of fuel or bulk of LO. (h.)

9. Additional operational procedures and general remarks. ( i.)

Oil Record Book: Part II

To be recorded:

1. Loading and unloading of oil cargo.

2. Internal transfer of oil cargo during voyage.

3. Cleaning of cargo tanks.

4. Crude Oil Washing (COW System only)

5. Ballasting of cargo tanks.

6. Ballasting of Segregated Clean Ballast Tanks (CBT Tankers only)

7. Discharge of dirty ballast.

8. Discharge of clean ballast contained in cargo tanks.

9. Discharge of ballast from Segregated CBTs. (CBT Tankers only)

10. Discharge of water from Slop Tanks into the sea.

11. Condition of ODM and Control System.

12. Accidental or other exceptional discharge of oil.

13. Additional operational procedures and general remarks.

14. Loading of ballast water. (Tankers engaged in specific trades)

15. Re-allocation of ballast water within the ship. (do)

16. Ballast water discharged to reception facilities. (do)

Shipboard Oil Pollution Emergency Plan: SOPEP.

Every oil tanker of 150GRT and above, and every ship of 400GRT and above, shall carry onboard a Shipboard Oil Pollution Emergency Plan.

The plan shall consist at least of:

1. Procedures to be followed by Master, or other person having charged of the ship, to report an oil pollution incident.

2. List of authorities or persons to be contacted, in the event of oil pollution incident.

3. Detailed description of actions to be taken immediately by persons onboard, to reduce or control the discharge of oil.

4. Procedures and point of contact onboard, for co-ordinating shipboard action with local authorities in combating the pollution.

Procedures, when accidental oil overflow occurs:

1. Notify Harbour/Terminal Authority immediately through the Master.

2. Actions immediately taken by persons onboard to stop, reduce or control the oil discharge.

3. Co-ordinate shipboard actions with local Authorities.

4. Inform owner, agent, P&I Club, Flag State Authorities, and vessels in vicinity.

5. Invite P&I (Protection and indemnity) correspondents.

6. Record in ORB, time & place of occurrence, approximate amount & type of oil, circumstances of discharge or escape.

Sludge Tank requirements:

1. Capacity must be minimum 1% of used HFO for 30 days (or)

½ % of used DO for 30 days.

2. Sufficient manholes to reach all parts of tank.

3. Adequate heating arrangement.

4. No direct connection between sludge tank discharge piping and overboard discharge piping.

5. Fitted with designated pump, having suitable capacity and discharge head.

6. Fitted with standard discharge connection.

7. Fitted with high level alarm.

Sludge Tank Capacity and Requirements:

For ship, which does not carry ballast water in oil fuel tank, minimum sludge tank capacity should be calculated as:

V = KCD m³

Where K = 0.01 for ship, where HO is purified for ME ( i.e. 1% )

K = 0.005 for ships using DO or HO, which does not require

purification before use ( i.e. ½ % )

C = Daily fuel oil consumption.

D = Maximum period of voyage between ports ( in days).

In absence of precise data, a figure of 30 days should be used.

Note: Sludge Tank Capacity (min) = 0.01 or 1% of used HFO for 30 days. [or]

0.005 or ½ % of used DO for 30 days.

Requirements:

1. Manhole

2. Heating coil

3. No direct connection to overboard.

4. Sludge pump.

5. International Discharge Connection.

6. High level alarm.

Biological Sewage Treatment Plant:

1. The unit is divided into 3 compartments: Aeration Chamber, Settling Chamber and Chlorinator.

2. Sewage enters Aeration Tank through soil inlet, and retained for about 24 hours and thoroughly mixed and aerated by aerators located at the bottom of the tank.

3. Aerobic bacteria and micro-organisms breakdown the organic waste and produce new bacteria cell.

4. Air, which provides oxygen for bacteria and micro-organisms, is supplied by Rotary Blowers to aerators.

5. The mixture is replaced by incoming sewage into Settling Tank, after passing through coarse screen.

6. All solids are precipitated in Settling Tank as Activated Sludge, which are then returned to Aeration Tank by airlift, and mixed with incoming raw sewage.

7. Clean liquid is displaced into Chlorinator, where remaining bacteria are killed.

8. Discharge of harmless effluent from Collecting Tank is controlled by Float Switch connected to Discharge Pump.

Important Equipment:

1. Two Rotary Blowers

2. Two Discharge Pumps.

3. Safety Valve at Aeration Blower.

4. High water level activating switch.

5. Low water level activating switch.

6. High water level alarm.

Biochemical Oxygen Demand, BOD:

- Amount of Oxygen taken up by Bacteria Incubation Process, in PPM.

Coliform Count:

1. Coliform is the name given to bacteria group, found in intestine.

2. Not normally harmful, but can cause Dysentery, Typhoid, and Gastro-enteritis.

3. Coliform Count checks effectiveness of disinfection.

4. Carried-out on effluent sample and incubating it for 24 – 48 hours at 35°C.

5. Coliform Bacteria count: 200/100 mlt. [Maximum].

Welding:

Welding on Cast Iron:

Oxy-acetylene Welding:

1. Flame adjusted with slightly excess acetylene, to get a temperature of

1200°C, [Melting point of CI].

2. Welding rod: pure CI with high silicon content.

3. Part to be welded is preheated to 600 ~ 700°C, to avoid excessive stresses.

4. During welding, gas bubbles are developed in molten weld pool. By striking the pool in circular motion with welding rod, these bubbles can be removed.

5. It is necessary to use welding flux.

Arc Welding:

1. Electrode: pure nickel (or) nickel iron.

2. Weld metal, deposited in short thin beads with small electrode and low amperage, to avoid local heat built up and expansion, around weld point.

3. Casting is allowed to cool, between each run.

Welding on Aluminium:

Gas Welding:

1. Used for thickness of plate up to 3/16″.

2. Slightly excess acetylene is used, due to lower melting point, 660°C.

3. Welding rod: Pure aluminium.

4. Necessary to use flux, to dissolve oxide.

5. Avoid inhalation of smoke, produced during welding.

Arc Welding:

1. Thickness of plate ¼ ” or more.

2. Electrode: 95% Aluminium, 5% Silicon: with 20°of vertical.

3. Keep arc as short as possible, low amperage and movement is in straight line.

4. Welding speed is 3 times faster than mild steel.

5. Thick plate should be preheated for smooth weld.

6. Traces of flux, removed with hot water after gas or arc welding, otherwise flux corrosion will occur.

Inert gas welding:

1. Welds are superior in strength and pressure tightness.

2. No flux is required, so no risk of corrosion.

3. Very high speed is possible with welding machine.

4. Gas metallic arc welding GMAW or MIG is easier to use, particularly where position welding is needed, vertical, horizontal or overhead.

5. For plate thickness of ¼ ” MIG is more economical and practical.

CE’s Instruction, regarding Welding Equipment handling:

1. Leather gloves, Safety shoes, helmet, and clean clothing [not oily Boiler Suit] to be worn.

2. Remove combustible material from vicinity.

3. Wear Safety Goggle when chipping and grinding.

4. One bucket of water and portable fire extinguisher kept near-by.

5. Cable connections, tight and well insulated.

6. To avoid Welding in confined spaces.

7. Never use oxygen and acetylene without attached pressure regulator.

8. Open oxygen cylinder valve slowly, and acetylene cylinder valve not more than 1½ turns.

9. Never attempt to mix any other with oxygen cylinder, and transfer or mix acetylene from one bottle to another.

10. Never use acetylene at a pressure higher than 15 psi [1kg/cm²].

Welding Distortion:

Depends upon:

1. Cooling rate.

2. Size of work.

3. Heat conductivity.

4. Melting point.

5. Welding speed.

6. Type of electrode.

Oxy-Acetylene Welding

- Never use Oxygen and Acetylene without pressure reducing regulators attached to cylinders.

- Open Oxygen cylinder valve slowly and fully.

- Open Acetylene cylinder valve not more than 1 turns.

- Use Acetylene at a pressure not higher than 15 psi (1 kg/cm²).

- Pressure ranges of 20 – 39 psi for Oxygen and 1 – 12 psi for Acetylene should be used depending on tip size, torch type and thickness of work.

Electric Arc Welding

- Electrode diameter 1/16″ Ampere controlled bet: 50 – 100 Amp.

Voltage 30 Volts

Thickness of plate up to 3/16″

- Electrode diameter 1/8″ Ampere controlled bet: 125 – 175 Amp.

Voltage 28 Volts

Thickness of plate above 1/2″

Electron Beam Welding:

1. A welding process directing high energy electron beam on workpiece (anode),

in a high vacuum chamber.

2. Applied to rare metal, and no electrode, no welding rod and no gases required.

3. This process can weld deeply in one pass, without overlapping.

4. Potential difference between cathode and anode is 15 kV.

Speed of electron flow, 140,000 miles/sec.

Testing of material:

1. Non- Destructive Test

2. Destructive Test.

Non- Destructive Tests:

Carried-out on components and not on test pieces:

1. Visual Probe

2. Electrical eddy current

3. Liquid penetrant

4. Magnetic particles

5. Ultra-sonic

6. Radiographic inspection

Destructive Tests:

Carried-out only on specimen, which are subjected to damage during testing.

1. Harness test

2. Impact test

3. Tensile test

4. Bend test

5. Creep test

6. Proof test

Arctic D steel:

» If part of ship’s structure is liable to particularly low temperature, a special type of steel known as Arctic D is used, as normal grade of steel is not suitable.

» Has higher tensile strength than normal mild steel.

» Has higher impact strength.

» Most important quality is its ability to absorb Impact value of 40 Joules at – 55°C,

in Charpy Impact test using standard specimen.

ISM Code:

IMO has adopted International Safety Management Code on 4th Nov 1993 for safe operation of ships and pollution prevention, in accordance with SOLAS, MARPOL and STCW.

Objectives:

1. To cover safety and pollution

2. To provide a framework for achievement of Total Quality System ISO 9002,

and ISM Code.

Purpose:

Safe management and operation of ship, and Prevention of marine pollution:

Mainly to ensure:

1. Safety at sea

2. Prevention of human injury or loss of life

3. Avoidance of damage to marine environment and property

Implementation:

Every shipping company should develop, implement and maintain Safety Management System SMS.

SMS includes following requirements:

1. Safety and Environmental Protection policy.

2. Instruction and procedure for safe operation of ship, and protection of environment, in compliance with International and Flag State Legislation.

3. Lines of communication between Shore-based and Shipboard personnel.

4. Procedures for reporting Accidents and Non-Conformities.

5. Procedures for preparedness and response, to emergency situations.

6. Procedures for Internal Audits and management reviews.

Documentation:

Quality/safety system should include following levels:

1. Quality/Safety Policy Manuals.

2. Quality/Safety Procedures Manuals.

3. Instruction Manuals.

Mandatory key dates:

1/7/98 applied to all passenger ships, bulk carriers, oil tankers, chemical and gas carriers. 1/7/2002 applied to all other cargo ships.

Certification:

Flag State Administration or Government or authorised body, issue Certificates

valid for 5-years, after thorough Audit.

Safety Management Certificate SMC:

- Issued to the ships, audited 2 ½ years after an Initial Audit, [within ± 6 months] and subjected to a Renewal Audit, before 5-years period has elapsed, but not later than 3 months before expiry date.

- It verifies that the company and its shipboard management operate in accordance with approved Safety Management System, SMS.

Interim SMC:

For ships that are taken-up into shipping company anew, and it is valid for 6 months.

Document of Compliance DOC:

» Issued to onshore organisation, which is audited annually after an Initial Audit, and subjected to a Renewal Audit, before 5-years period has elapsed, but not later than 3 months before expiry date.

Interim DOC:

For a new company, valid for 12 months, or for an existing company if new ship-type enters the company’s fleet, valid for 6 months.

General Checklist for Audit:

1. Certificates and documents including ORB, Logbooks.

2. Safety in general.

3. Testing and drills.

4. Navigation equipment.

5. LSA.

6. FFA.

7. Radio installation including GMDSS.

8. Load Line.

9. Machinery in ER.

10. Electrical equipment.

11. Mooring equipment.

12. Cargo gears.

13. Hull construction.

14. Marine pollution.

15. Accommodation.

Main Drills in ISM:

1. Lifeboat Drill

2. Fire Drill

3. Abandon Ship Drill

4. Man Overboard Dill

5. Enclosed Space Rescue Drill

6. Oil Spill Response Drill

7. Emergency Steering Gear Drill

SMC:

Issued by;

Administration

Organization recognized by Administration.

DOC:

Issued by;

Administration

Organization recognized by Administration

Another contracting government recognized by Administration.

CE hand over / take over:

1. Discuss with outgoing CE about machinery condition and standing order from HO.

2. To read, hand over note / maintenance record.

3. Check logbook at least for last 3-months, CMS quarterly list, Survey items, previous voyage report ORB up-to-date filling, garbage book, sludge formation compared with 1% of voyage fuel consumption, sludge remaining onboard, all certificates, documents, and validity such as IOPP, ISPP etc:

4. Take all FO, LO tank soundings, calculate ROB, based on API gravity method, and check with log entry. Ensure fuel consumption is enough for next port or next bunker port.

5. Check all running machinery, MARPOL equipment, OWS, incinerator, sewage plant, FFA, emergency generator, quick closing arrangement and lifeboat engine.

6. Check standard spares and store, special tools and measuring equipment.

7. If everything is OK, sign the hand over note.

CE’s Routine Works:

i. Every morning: Round check of operating machinery and engine room,

Discuss with 2/E, about ER repair and maintenance jobs.

Discuss with master, about ship situation and company instruction.

ii. At noon: To check ER logbook, FO, LO, DO consumption and ROB,

Performance and running hours of machinery.

Prepare Noon Report.

iii. Once a month: Fuel and LO onboard.

Store and spare inventory.

Maintenance report and breakdown report.

iv. Every voyage: Voyage Report.

CE reports: includes confidential report, voyage report, LO and FO consumption report, maintenance report, repair list, store and spare report and vouchers.

Joining a vessel, which is not commissioned. (New ship delivery)

1. Check Specifications and Class Requirements thoroughly.

2. Inspect the works of shipyard staff for final acceptance. Unsatisfactory works should be informed to company representatives and dockyard manager.

3. All alignment and clearance measurement works, witnessed by CE.

4. Before closing the tank manholes, make final inspection.

5. Before undocking, all underwater jobs must be completed and checked by CE.

6. Check the list of spares to be supplied, and inform if necessary items are missing.

7. Received spares properly stored and recorded.

8. Make familiar with all the layout of machinery, piping, cooling arrangement, etc.

9. Check fire fighting system, and location of remote stops and shut-off devices.

10. When other engineers arrived, CE must explain the layout and operations of machinery.

11. All initial records, ideal conditions, shop test records, trial test records must be kept for the whole life of ship.