http://marinestudy.net/ship-motons-and-stresses/ship-motion-stresses/

Category Archives: Maritime Technology

F.O. PURIFIER

What is purifier and why we use it on board?

As the name implies, Purifier purifies fuel oil used on board. It is a machine that separates impurities from fuel oil. Impurities can be both solid and liquid/water.

Why there are impurities in fuel oil?

Crude oil is refined in the refinery and produces various fine products. Marine residual fuel is the last product in terms of purity in the refining process.

Besides to make the process more economic silica-alumina is used to break the heavier molecules lighter. This silica-alumina often is not possible to remove completely.

The amount of impurities depends upon the source of crude oil and quality of refining process.

Principle of operation:

Oil, water and other impurities are of different density. Whenever the oil is subjected to centrifugal force heavier particles (water and solid) will be thrown outside and lighter particles will remain close to the center.

Difference between Purifiers and Clarifiers:

Functional difference: Purifiers can separate two liquids of different densities due to centrifugal force. i.e. water and solid particles from fuel. Purifiers can also remove small amount of solids.

Clarifiers remove solid particles from the fuel oil. Clarifiers will also remove small quantities of water.

Purifiers may be arranged to used as clarifier.

Constructional difference: Purifiers have gravity disc whereas clarifier has no gravity disc.

Clarifier has no sealing water as handles only one liquid i.e: fuel oil. So there is no interface inside clarifier.

Purifiers have two liquid out: one for liquid oil and another for water.

Clarifiers have only one liquid outlet.

Main components of purifier:

Bowl body: Bowl body is connected with the vertical shaft by a lock nut. It houses the main bowl. Main bowl slides within the bowl body to facilitate de-sludge operation and to make seal with bowl hood.

Main bowl: Unpurified oil accumulates in the main bowl. It moves up and down by water pressure to facilitate sludge discharge mechanism.

Bowl hood: The cylindrical shaped hood makes seal with main bowl so that oil cannot leak out. It houses the main seal ring for the sealing purpose.

At the top it houses dam ring/gravity disc, impeller.

Discs:

These discs provide a way for the cleaned purified oils to go upward in a separate path through the holes cut into them.

Gravity disc:

It maintains the interface between oil and water. It is done by the inner diameter of the gravity disc.

If the diameter is increased more water will get its way to escape the bowl. The amount of water will be reduced, so the force exerted by the water will also reduce. The force exerted by oil will push the oil-water interface towards periphery. If the diameter increases more, the interface will move towards a position where oil will escape through water line. i.e: overflow.

Centripetal impeller: Oil collected from purifiers will be drawn inside and delivered by this impeller.

Inlet pipe: As the name implies fuel oil gets inside the bowl by the inlet pipe.

Distributor: Feed oil is introduced through feed inlet pipe and the distributor to the main bowl chamber.

Vertical shaft: The revolution of the horizontal shaft transmitted and increased by vertical shaft gear teeth and the bowl rotates at the top. Bowls are supported by upper bearing housing arrangement.

Purifier rpm and motor rpm:

Motor runs at a rpm of 2000-2500 rpm and purifier bowl rotates around 15000-18000 rpm. This is done by increased gear mechanism of horizontal shaft.

Horizontal shaft: It is connected with motor via frictional block arrangement. Bearings in the bearing housings are provided at two ends of the shaft. Between them spiral gear is fitted.

Water supply device: Underneath the bowl body cylinder water supply device is fitted to supply low and high pressure operating water.

Low pressure operating water used to close the main cylinder.

High pressure operating water used to perform sludge discharge.

Frictional block, frictional pulley and frictional boss : Motor is not directly coupled with the purifier’s horizontal shaft. Friction blocks are used for soft starting and acceleration of the motor and hence avoid the motor being overloaded. There are arrangements to house frictional blocks which will rotate as the same rpm of motor.

During start up the motor will run in slow rpm and so do the friction block. These blocks due to centrifugal force will keep hitting the circular frictional block of the horizontal shaft. So the horizontal shaft will start to move.

Connecting the motor with the horizontal shaft directly would cause huge load on the motor at starting and motor to trip.

Brake:

To stop the purifiers in emergency this break is used to stop the rotation immediately. The brake linings are pressured against the outer surface of the pulley to stop purifier rotation.

External equipment in the purification system:

Gear pump:

To supply fuel oil to the purifier external feed is fitted. Either the pump is driven by an electrical motor or the pump is attached by a safety joint with the horizontal shaft.

Heaters: Purifiers are fitted with heaters to facilitate fuel oil heating.

Factors influence the interface:

Through put/ Feed rate

Temperature of the fuel

Diameter of the gravity disc

Density of the fuel

Through put:

If the feed rate is excessively increased

- The increased feed rate will increase the mass of fuel.

- The increased mass of fuel will exert more force to push the water out of bowl.

- This will cause the water-oil interface to move towards periphery and cause overflow.

It is of vital importance to run the purifiers with optimum feed rate. High feed rate reduces purification efficiency. Feed rate depends upon fuel consumption of the ship.

Running with low feed rate will cause the fuel oil service tank level to decrease. If feed rate not adjusted for long time

Normally, feed rate should be 110 percent of the fuel consumption.

Temperature of the fuel:

Temperature plays an important role to maintain oil-water interface.

- If temperature increases the density of oil reduces.

- The force exerting by oil reduces.

- Oil-water interface tend to move towards center.

Diameter of Gravity disc:

It is also known as dam ring.

Gravity disc inner diameter determines the amount of sealing water inside the bowl.

Thus it also determines the position of the oil-water interface.

If the diameter increases interface moves toward periphery of the bowl.

If the diameter reduces interface moves toward center.

Density of oil: An increase in density will also results in increase of mass and centrifugal force to push more water out of the bowl. i.e. interface will move towards periphery.

To handle with high density oil gravity disc diameter has to be decreased and temperature has to be maintained.

Operational sequence:

- Gain rpm of the motor and purifier.

- Bowl close: Low pressure operating water will push the main bowl up and make seal with top hood.

- Sealing water: From the top via the inlet line sealing water will be supplied to fill up the full chamber. At this stage full chamber is filled with water.

- Sludge discharge: High pressure operating water will push the pilot valve or spring loaded valve plate to drain the water that used to make the seal with top hood. The seal will break and sludge will be thrown out of the main bowl.

- Again main bowl closes by low pressure water.

- Sealing water supplied to fill the chamber.

- Fuel oil is supplied inlet via inlet pipe through distributor.

- By centrifugal force impurities and water will be thrown outside and purified light oil will get its way through the drilled hole. The light oil will be guided by top disc to the centripetal pump to the service tank.

Sludge discharge/ De-sludge:

An important function of purifier is sludge discharge operation. It removes the accumulated sludge inside the bowl at either set time interval or manually.

Different makers have different methods of discharging. But basic principle is almost same.

Low pressure operating water/ bowl closing water will enter through solenoid valve for predetermined time and then stop.

This water will gain energy due to centrifugal movement of the bowl. The centrifugal force will push the main bowl up and make seal with the top hood.

Sealing liquid will enter inside the bowl through inlet pipe from the top for set time.

The sealing liquid will occupy the full bowl chamber.

High pressure water/ bowl opening water acts on the lower side of the pilot valve. It acts relatively on large surface area than the low pressure water that acts on the upper side of the pilot valve and causes the operating water to drain off through the drain orifice.

This drainage of water will cause the main bowl to fall down. Hence the seal will break. The sludge inside the bowl comes out of bowl with force. High pressure water will be injects for set period of time.

Instead of pilot valves in some designs, spring plates are used.

Safety features of purifiers:

- Low back pressure alarm

- High temperature alarm

- Safety joint of feed pump

Properly tightening:

Some parts of the purifiers are secured by screws and nuts. It is of vital importance to tighten all lock nuts and crews are perfectly. The tally marks on the body of the parts must match perfectly.

- Bowl nut

- Disc nut

- Cap nut of vertical shaft

- Set bolts of frame

- Lock nut of inlet pipe.

Regular checks:

- Fuel temperature and feed rate

- Any abnormal vibration

- Purifier motor load

- Crankcase oil level and color.

- Any leakage.

Dealing with different grade of fuel:

If there is any change of fuel grade the gravity disc has to be changed according to the specific gravity of the fuel. The gravity disc inner diameter can be obtained from the monogram provided in the manual.

Selection of gravity disc inner diameter for fuel oil.

Suppose the specific gravity of fuel at 15 ⁰C is 0.93, operating temperature 80 ⁰C and feed rate is 1200 l/h. Diameter for the operating data will be 72mm.

Here, the blue line represents the fuel oil specific gravity which intersects operating temperature (80 ⁰C, marked yellow) at point C. Draw a parallel line to the X axis (Separating temperature axis) and extends up to 100 ⁰C. Connect the right end of the line with the 1200 L/h point. It will intersect the gravity disc inner diameter line at 72mm.

IGNITION QUALITY PARAMETERS OF SLOW SPEED DIESEL ENGINE

Ignition quality parameters:

- Energy

- Viscosity

- Maximum firing pressure.

4. Injection delay

5. Ignition delay .

1. Energy comparison

• The injection pump is a volumetric pump

• The higher the density the more energy it contains per volume unit

• The density difference between HFO and MDO is larger than the difference in net calorific value

2. Viscosity comparison

- The viscosity of MDO is lower than the viscosity of HFO (even HFO is heated)

• Lower viscosity fuels result in more internal leakage in the injection pump from the high pressure side to low pressure side.

• Internal leakage has to be compensated by giving more fuel rack

3. Maximum firing pressure

- Dependent on the charge air pressure

• To achieve proper combustion, the firing pressure has to be high and thus also the charge air pressure

• Timing of the fuel pump

4. Injection delay

- Injection delay is the time it takes to build up a pressure higher than the opening pressure of the nozzle.

• Normally 4…5 ° of crank angle

• The delay is comparable to the condition of injection equipment

5. Ignition delay

- is the time gap between the commencement of injection and the commencement of ignition.

- Dependent on the fuel quality

- Compression temperature has a big influence on the ignition delay

- Compression temperature is not high enough for the fuel to ignite longer ignition delay

Source: Wartsila

Besides consider the following for better ignition quality of slow speed diesel engine:

Higher peak pressures and higher exhaust gas temperatures:

• Normally 1…2 ° of crank angle.

• Too early timing of injection

• Higher peak pressure

Exhaust gas temperature after cylinder:

- Measured individually after each cylinder

- Each cylinder has two measuring

- The average temperature of all exhaust temperature sensors is approximately 100 °C lower than the exhaust gas temperature before the turbine.

- Maximum allowed difference between valves in one

- Maximum allowed difference of one cylinders average from the average of the all cylinders ,

- In normal operation the average temperature Cylinder temperature deviation can be up to 30 – 40 °

- Engine is (depending of installation) provided with a safety slow down arrangement if the temperature difference is too big

- A 10 °C increase in ambient temperature will result approximately 15 °C increase in exhaust gas temperature

Exhaust gas temperature after turbocharger:

- Indicates the kinetic energy of the exhaust gases that are running the turbine

- Indicates the condition of the turbo, e. scavenging of the engine

- If a de-Nox catalysator is installed the temperature has to exceed certain level to ensure the function of the catalysator.

Pressure difference over the cylinders:

- Measuring the pressure difference between charge air manifold and exhaust gas

- gives an indication of how well the scavenging works.

- Depends on the turbocharger, therefore values below should be considered as allusive

- The bigger the Dp is the better

- Is normal value with 100% load varies depending of installation once the value has been dropped down, it is an indication that something is wrong with the engine -e.g. dirty nozzle ring & turbine

Written from the news letter of Wartsila.

MAIN ENGINE AIR STARTING SYSTEM

STAR-DELTA STARTING OF THREE PHASE MOTOR

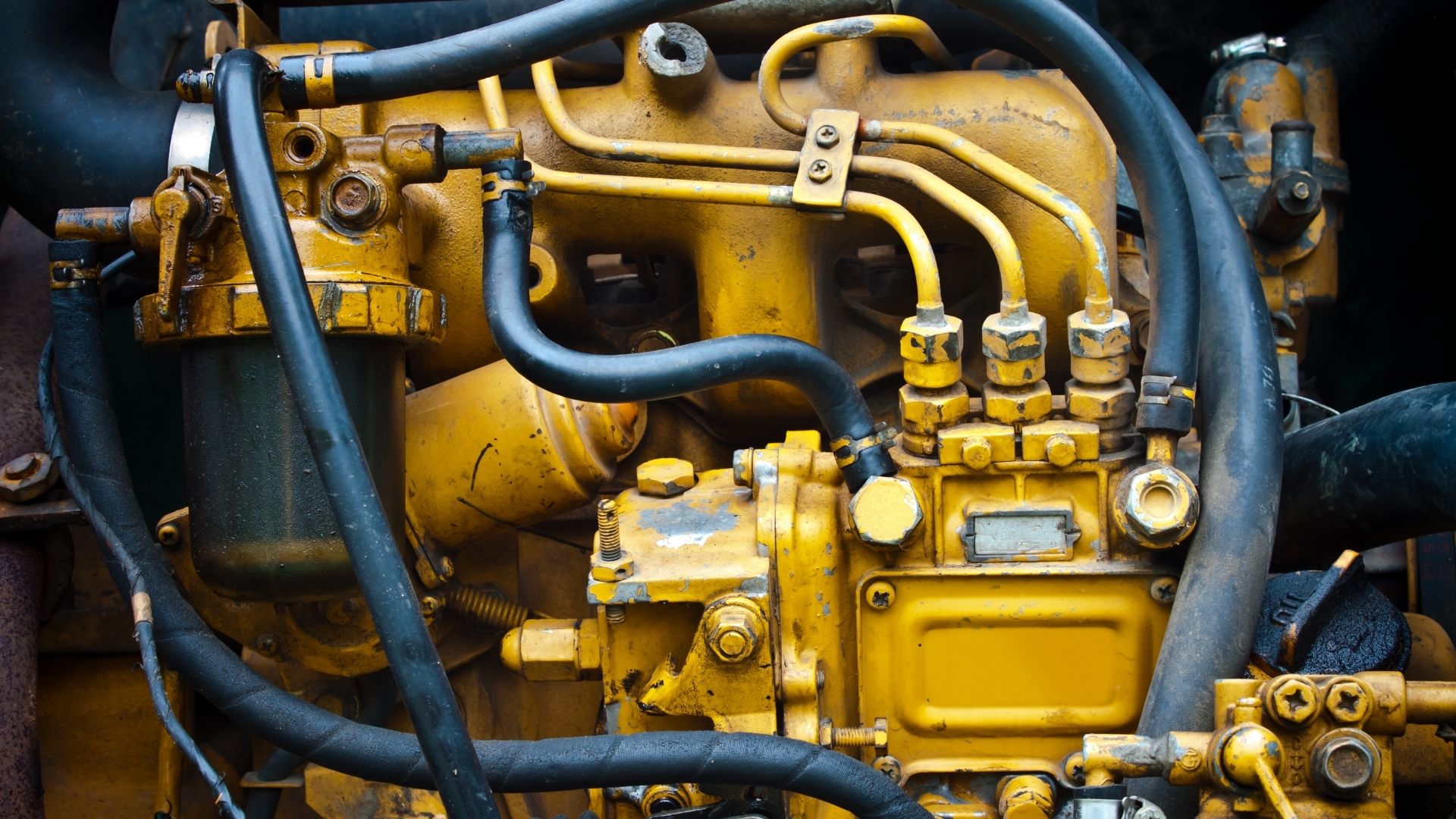

DIESEL ENGINE CRANKCASE EXPLOSION

INTRODUCTION:

For any fire to begin, the fire tringle needs to be completed. To complete a fire tringle there must be present of a combustible material, oxygen or air to support combustion and a source of heat in proportional ratio and within the flammable limits, the reaction which causes fire or explosion becomes cyclic.

Image Credit: www.brighthubengineering.com

Crankcase explosion normally occurs in trunk engine in which the lubricating oil used in the bearings is splashed around the crankcase and broken down into moderate size particles.

The main cause of crankcase explosions are the development of hot spots at various places in the crankcase. Due to the reciprocating motion of the piston the lubricating oil in the crankcase is splashed in the air.

Image Credit: www.marinediesels.info

Possible causes of “hot spots” in diesel engines:

Failure of oil supply

Bearing journal surfaces becoming too rough due to L.O. becoming corrosive or being polluted by abrasive particles

Atomization of circulating oil, caused by a jet of air/gas by combination of the following:

– Stuffing box leakages (not air tight)

– Blow-by through a cracked piston crown or piston rod (with direct connection to crankcase via the cooling outlet pipe)

– As a result of heat from a scavenge fire being transmitted down the piston rod via the stuffing box

Image Credit: www.marinediesels.info

When there is a hot spot formed example a bearing, guide, connecting rod, piston trunk or skirt become overheated, the falling oil particles to the heated area easily vaporize and form a white vapour (in addition some is broken down to flammable gasses such as Hydrogen and acetylene) which spreads around the crankcase.

Some of the vapour condenses to form very small particles (up to 200 micro meters in diameter) which may eventually permeate or travel the away from hotspot to whole of the crankcase space. The condensed droplets, form a dense white mist If the mixture of air, very small particles and vapour reaches a certain proportion and the temperature of the hot spot is high enough to initiate combustion an explosion can occur (850°C to ignite oil mist).

Although the most common cause of of a localized hotspot is due to friction, it is not the only cause of a crankcase explosion. A cracked piston crown, blow-by or an external fire have caused crankcase explosions in the past.

If the mixture of oil vapour, particles and air too rich (due to some reason or possibility air can be drawn in so creating the environment for a second and possible larger explosion.

EXPLOSIONS – PRIMARY AND SECONDARY

PRIMARY EXPLOSION:

Over a period of time the formation of mist starts increasing and when sufficient air/fuel ratio is reached i.e. high enough to exceed the lower explosion limit, the mist comes in contact with the hot spot again and in the presence of sufficient temperature results into an explosion.

The extent of explosion will depend upon the amount of mist produced inside. The primary explosion might be mild and sufficient enough to lift the crankcase relief valves but there could be more severe and dangerous effects during secondary explosion.

Source: www.marinediesels.co.uk

SECONDARY EXPLOSION:

When an explosion occurs a flame front travels down the crankcase with a pressure wave in front of it.

The turbulence caused by moving engine components causing churning and mixing of vapours increase the speed of the flame front and its area, which contribute to the increase in pressure.

Turbulence caused by venting of the pressure through relief valves can also influence the explosion.

Following the venting of the explosion through the relief valves, there is a drop in crankcase pressure to below atmospheric pressure. This can cause air to enter the crankcase resulting in another flammable mixture to be developed resulting in a secondary explosion to occur.

The secondary explosion is more violent and can result in crankcase doors being blown off the engine, and fires starting in the engine room. If the relief valves do not reseal after lifting, or if they do not lift at all in the primary explosion ( due to lack of maintenance etc), then door(s) may be blown off in the primary explosion, giving a ready path for the ingress of air, which will make a secondary explosion more likely.

Air can also be sucked in via the crankcase vent, although rules state that this must be as small as practicable and new installations must have a non return valve fitted.

INDICATION OF CRANKCASE EXPLOSION:

It is a bit difficult to read the early signs of a crankcase explosions. This is because the indications are similar to many other emergency situations. But there are few pre-explosion signs that can be read. Crankcase explosion will lead:

Sudden increase in the exhaust temperature

Sudden increase in the load on the engine

Irregular running of the engine

incongruous noise of the engine

smell of the white mist.

In case of these indications, engine speed should be brought down immediately and the supply of fuel and air should be stopped. The system should then be allowed to cool down by opening the indicator cocks and turning on the internal cooling system.

MEASURES TO BE TAKEN WHEN OIL MIST HAS OCCURRED

Do not stand near crankcase doors or relief valves – nor in corridors near doors to the engine room casing!

Reduce speed/pitch to slow-down level, if not already carried out automatically

Ask the bridge for permission to stop

– Measures to be taken when Oil Mist has occurred

When the stop order is received:

– Stop the engine

– Close the fuel oil supply

Switch-off the auxiliary blowers

Open the skylight and/or “stores hatch”

Leave the engine room

– Measures to be taken when Oil Mist has occurred

Lock the casing doors and keep away from them

Prepare the fire-fighting equipment

Do not open the crankcase until at least 20 minutes after stopping the engine. When opening up, keep clear of possible spurts of flame. Do not use naked light and do not smoke.

– Measures to be taken when Oil Mist has occurred

Stop the circulating oil pump. Take off/open all the lowermost doors on the side of the crankcase. Cut-off the starting air and engage the turning gear.

Locate the “hot spot”. Use powerful lamps from the start.

Keep possible bearing metal found at the bottom of oil tray for later analyzing.

– Measures to be taken when Oil Mist has occurred

Prevent further “hot spots” by preferably making a permanent repair.

Ensure that the respective sliding surfaces are in good condition

Take special care to check the circulating oil supply is in order.

– Measures to be taken when Oil Mist has occurred

Start the circulating oil pump and turn the engine by means of the turning gear.

Check the oil flow from all bearings, spray pipes and spray nozzles in the crankcase, chaincase and thrust bearing.

Check for possible leakages from piston or piston rods.

PREVENTION

Prevention of crankcase explosion can be done by preventing the generation of hot spots. It can also be prevented by the following ways:

By providing proper lubrication to the reciprocating parts,thus avoiding high temperatures.

Avoiding overloading of the engine

Using bearings with white metal material which prevents rise in temperature.

Using oil mist detector in the crankcase with proper visual and audible alarm.Oil mist detectors raise an alarm if the concentration of oil mist rises above the permissible limit.

Pressure relief valves should be fixed on the crankcase for the instant release of pressure. They should be periodically pressure tested.

Crankcase doors should be made of strong and durable material. Vent pipes shouldn’t be too large and should be checked for any choke up

Pressure relief valves should be provided with wire mesh to prevent the release of flames inside the engine room.

Safe distance should be kept from the crankcase and the relief valves in case the indications are sighted.

In case of indication, the crankcase doors should never be opened till the time the system has totally cooled down. Once the system has cooled down, proper inspection and maintenance should be carried out.

Fire extinguishing medium should be kept standby. In many systems, inert gas flooding system is directly connected to the crankcase.

Crankcase safety fittings

• Crankcase Relief valves

• Vent pipes

• Alarms

• Warning notice

• Fire-extinguishing system for scavenge manifolds

Relief Valves

The valve lids are to be made of ductile material capable of withstanding the shock of contact with stoppers at the full open position.

The discharge from the valves is to be shielded by flame guard or flame trap to minimize the possibility of danger and damage arising from the emission of flame.

Number of Relief Valves

In engines having cylinders not exceeding 200 mm bore and having a crankcase gross volume not exceeding 0,6 m3, relief valves may be omitted.

In engines having cylinders exceeding 200 mm but not exceeding 250 mm bore, at least two relief valves are to be fitted; each valve is to be located at or near the ends of the crankcase. Where the engine has more than eight crank throws an additional valve is to be fitted near the centre of the engine.

In engines having cylinders exceeding 250 mm but not exceeding 300 mm bore, at least one relief valve is to be fitted in way of each alternate crank throw with a minimum of two valves. For engines having 3, 5, 7, 9, etc., crank throws, the number of relief valves is not to be less than 2, 3, 4, 5, etc., respectively.

In engines having cylinders exceeding 300 mm bore at least one valve is to be fitted in way of each main crank throw.

Additional relief valves are to be fitted for separate spaces on the crankcase, such as gear or chain cases for camshaft or similar drives, when the gross volume of such spaces exceeds 0.6 m3.

Size of Relief Valves

The combined free area of the crankcase relief valves fitted on an engine is to be not less than 115 cm2/m3 based on the volume of the crankcase.

The free area of each relief valve is to be not less than 45 cm2.

The free area of the relief valve is the minimum flow area at any section through the valve when the valve is fully open.

In determining the volume of the crankcase for the purpose of calculating the combined free area of the crankcase relief valves, the volume of the stationary parts within the crankcase may be deducted from the total internal volume of the crankcase.

Vent Pipes

Where crankcase vent pipes are fitted, they are to be made as small as practicable to minimize the inrush of air after an explosion. Vents from crankcases of main engines are to be led to a safe position on deck or other approved position.

If provision is made for the extraction of gases from within the crankcase, e.g. for oil mist detection purposes, the vacuum within the crankcase is not to exceed 25 mm of water.

Lubricating oil drain pipes from engine sump to drain tank are to be submerged at their outlet ends. Where two or more engines are installed, vent pipes, if fitted, and lubrication oil drain pipes are to be independent to avoid intercommunication between crankcases.

Alarms

Alarms giving warning of the overheating of engine running parts, indicators of excessive wear of thrusts and other parts, and crankcase oil mist detectors are recommended as means for reducing the explosion hazard. These devices should be arranged to give an indication of failure of the equipment or of the instrument being switched off when the engine is running.

Warning Notice

A warning notice is to be fitted in a prominent position, preferably on a crankcase door on each side of the engine, or alternatively at the engine room control station. This warning notice is to specify that whenever overheating is suspected in the crankcase, the crankcase doors or sight holes are not to be opened until a reasonable time has elapsed after stopping the engine, sufficient to permit adequate cooling within the crankcase.

Crankcase Access and Lighting

• Where access to crankcase spaces is necessary for inspection purposes, suitably positioned rungs or equivalent arrangements are to be provided as considered appropriate.

• When interior lighting is provided it is to be flameproof in relation to the interior and details are to be submitted for approval. No wiring is to be fitted inside the crankcase.

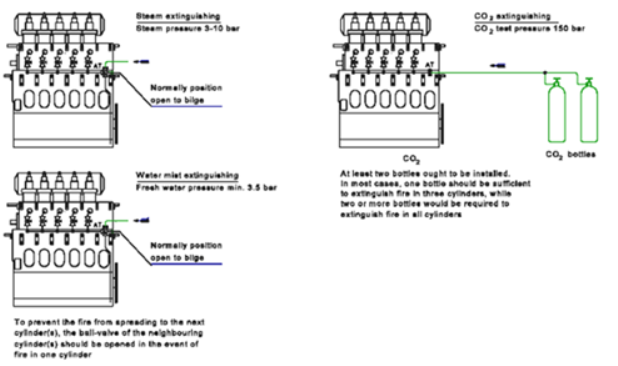

Fire-Extinguishing System for Scavenge Manifolds

• Crosshead type engine scavenge spaces in open connection with cylinders are to be provided with approved fixed or portable fire-extinguishing arrangements which are to be independent of the fire-extinguishing system of the engine room.

SPECIFIC REGULATIONS

1. Non-return doors must be fitted to engines with a bore greater than 300mm, at each cylinder with a total area of 115sq.cm/m3 of gross crankcase volume. The outlets of these must be guard to protect personnel from flame. For engines between 150 to 300mm relief doors need only be fitted at either end. Below this bore there is no requirement. The total clear area through the relief valve should not normally be less than 9.13cm2/m3 of gross crankcase volume

2. Lub Oil drain pipes to the sump must extend below the surface and multi engine installations should have no connections between the sumps

3. Large engines, of more than 6 cylinders are recommended to have a diaphragm at mid-length and consideration should be given to detection of overheating (say by temperature measuring probes or thermal cameras) and the injection of inert gas.

4. Engines with a bore less than 300mm and a crankcase of robust construction may have an explosion door at either end

5. Means of detection of oil mist fitted.

Crankcase Doors

• These when properly designed are made of about 3mm thick steel with a dished aspect and are capable of withstanding 12 bar pressure. They are securely dogged (gripped) with a rubber seal arrangement.

Crankcase Relief Door

Due to the heavy force of momentum the gas shockwave is not easily deflected.

Thus any safety device must allow for a gradual change in direction, and be of the non-return type to prevent air being drawn back into the crankcase.

The original design was of cardboard discs which provided no protection against the ingress of air after the initial explosion, in addition it was known for these discs to fail to rupture in the event of an explosion.

The valve disc is made of aluminium to reduce inertia.

The oil wetted gauze provides a very effective flame trap this reduces the flame temperature from 1500’C to 250’C in 0.5 m.

The ideal location for this trap is within the crankcase where wetness can be ensured.

The gas passing from the trap is not normally ignitable. The gauze is generally 0.3mm with 40% excess clear areas over the valve.

Continuous extraction by exhauster fan may be used but this tends to be costly, flame gauzes must be fitted to all vents. Similarly a continuous supply of air can be used to reduce gas mist levels.

Crankcase oil mist detector

Source: OIL MIST DETECTOR MD-SX (Daihatsu, Japan)

Oil mists can be readily detected at concentrations well below that required for explosions, therefore automated detection of these oil mists can be an effective method of preventing explosions.

The Graviner oil mist detector is in common use in slow speed and high speed engines.

The disadvantage of this type if system is that there is a lag due to the time taken for the sample to be drawn from the unit and for the rotary valve to reach that sample point.

Consists of :-

I. Extraction fan

– draws the sample from the sample points through the reference and measuring tubes via non-return valves.

II. Reference tube

– measures the average density of the mist within the crankcase, as there will always be some mechanically generated mist.

III. Rotary valve

– this valve is externally accessible and is so marked so as to indicate which sample point is on line. In the event on exceeding the set point , the valve automatically locks onto that point so giving a clear indication of the locality of the fault condition.

IV. Measuring tube

– measures the opacity(darkness) of the sample by means of a photoelectric cell as with the measuring cell. To exclude variables in lamps a single unit is used with beams directed down the tube by mirrors.

Oil mist detector function:

- To monitor samples taken continuously from the crankcase of a diesel engine.

- Detect the presence of oil mist at concentrations well below the level at which crankcase explosions may occur. This gives warning in time to allow avoiding to slow down the engine and prevent either serious bearing damage or an explosion.

- The detector consists basically of two parallel tubes of equal size each having a photo-electric cell fitted at one end. Photo-electric cells are light sensitive and generate an electric current directly proportional to the intensity of the light falling on their surface. Lenses are fitted to seal the ends of each tube but allow light to pass.

- Two identical beams of light from a common lamp are reflected by mirrors to pass along the tubes on to the cells which are then in electrical balance.

- One tube is sealed to contain clean air and is termed the reference tube. The other termed the measuring tube, has connections through which samples of the vapor content of the engine crankcase are drawn by means of an electrically extractor fan.

- In the event of a concentration of oil mist being present in the sample, light will be obscured before reaching the cell of the measuring tube. Electrical balance between the two cells will be disturbed and an alarm will be operated.

- Sampling points should be fitted to each cylinder crankcase and their connections are brought to a rotating selector valve which is driven from the motor. This repeatedly connects each sampling point to the measuring tube in sequence.

- In the event of oil mist being detected the rotator stops to indicate which sampling point is concerned. The instrument must be reset below the alarm ceases and sampling will recommence its sequence.

Crankcase oil mist detector maintenance:

- Sampling connections should not exceed 12.5 meters in length and must slope to ensure positive drainage of oil; they must avoid any loops in which could fill with oil.

- The detector should be tested daily and the sensitivity checked. The lenses and mirrors should be cleaned periodically.

REFERENCES:

- www.marineengineering.co.uk

- The Running and Maintenance of Marine Machinery – Cowley

- Lamb’s Question and Answers on Marine Diesel Engines – S. Christensen

- Diesel Engines – A J Wharton

- www.marinediesels.info

DIESEL ENGINE SCAVENGE FIRE

INTRODUCTION:

For any fire to begin, the fire tringle needs to be completed. To complete a fire tringle there must be present a combustible material, oxygen or air to support combustion and a source of heat at a temperature high enough to start combustion.

Source: www.marinediesels.info

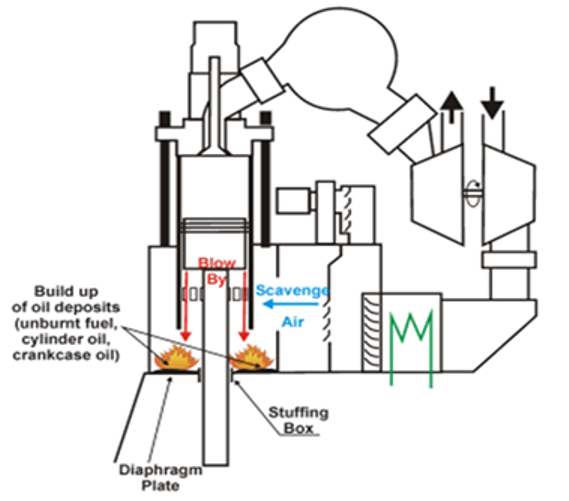

In the case of scavenge fires:

the combustible material is oil. The oil can be cylinder oil which has drained down from the cylinder spaces, or crankcase oil carried upwards on the piston rod because of a faulty stuffing box. In some cases the cylinder oil residues may also contain fuel oil. The fuel may come from defective injectors, injectors with incorrect pressure setting, fuel particles striking the cylinders and other similar causes.

The oxygen necessary for combustion comes from the scavenge air which is in plentiful supply for the operation of the engines.

The source of heat for ignition comes from piston blow-by, slow ignition and afterburning, or excessive exhaust back pressure, which causes a blowback through the scavenge ports.

• A scavenge fire can cause serious damage to the piston rod diaphragm gland as well as leading to possible distortion of the air box and cracking of the liner. Tie rod tension will almost certainly be affected.

• The worst case scenario for a scavenge fire is it leading to a crankcase explosion

• The fire may also spread outside the scavenge box due to relief doors leaking or oil deposits on the hot casing igniting. For these reasons a scavenge fire should be dealt with as quickly as possible.

INDICATION

Loss in power and irregular running of the engine,

High exhaust temperatures of corresponding units,

High local temperature in scavenge trunk,

Surging of turbocharger,

Sparks and smoke emitted from scavenge drains.

External indications will be given by a smoky exhaust and the discharge of sooty smuts or carbon particles.

If the scavenge trunk is oily the fire may spread back-from the space around or adjacent to the cylinders where the fire started and will show itself as very hot spots or areas of the scavenge trunk surfaces.

In ships where the engine room is designed as UMS, temperature sensors are fitted at critical points within the scavenge spaces. So, activation would cause automatic slow down of the engine.

ACTION TO BE TAKEN WHEN SCAVENGE FIRE OCCURRED

In the event of scavenge fire the engine must be put to dead slow ahead as soon as possible and the fuel must be taken off the cylinders affected by the fire or preferably stopped.

The turning gear should be put in and the engine continuously turned with increased cylinder oil to prevent seizure (jam).

All scavenge drains must be shut to prevent the discharge of sparks and burning oil from the drains into the engine room.

Air supply should be cut off by enclosing the turbocharger inlets, for mechanically operated exhaust valves the gas side should also be operated, (hydraulically operated exhaust valves will self close after a few minutes).

For a minor scavenge fire:

– A minor fire may shortly burn out without damage, and conditions will gradually return to normal. The affected units should be run on reduced power until inspection of the scavenge trunking and overhaul of the cylinder and piston can be carried out at the earliest safe opportunity.

– Once navigational circumstances allow it, the engine should be stopped and the whole of the scavenge trunk examined and any oil residues found round other cylinders removed.

– The actual cause of the initiation of the fire should be investigated

For a major scavenge fire:

– If the scavenge fire is of a more major nature, if there is a risk of the fire extending or if the scavenge trunk is adjacent to the crankcase with risk of a hot spot developing it sometimes becomes necessary to stop the engine.

– Normal cooling is maintained, and the turning gear engaged and operated. Fire extinguishing medium should be applied through fittings in the scavenge trunk: these may inject carbon dioxide, dry powder or smothering steam.

The fire is then extinguished before it can spread to surfaces of the scavenge trunk where it may cause the paint to start burning if special non inflammable paint has not been used.

Boundary cooling of the scavenge trunk may be necessary. Keep clear of scavenge relief valves, and do not open up for inspection until the engine has cooled down.

After extinguishing scavenge fire:

After extinguishing the fire and cooling down, the scavenge trunking and scavenge ports should be cleaned and the trunking together with cylinder liner and water seals, piston, piston rings, piston skirt, piston rod and gland must be inspected.

Heat causes distortion and therefore checks for binding of piston rod in stuffing box and piston in liner must be carried out.

Tightness of tie bolts should be checked before restarting the engine.

Inspect reed valves if fitted, and scavenge relief valve springs.

Fire extinguishers should be recharged at the first opportunity and faults diagnosed as having caused the fire must be rectified.

SAFETY FITTING

- Scavenge belt relief door

- Fire Fighting Media

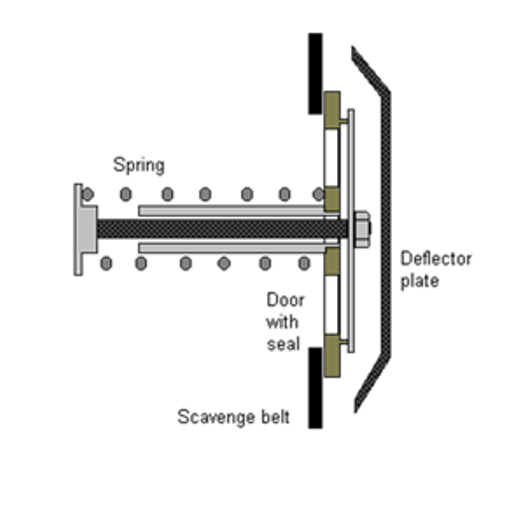

1. SCAVENGE BELT RELIEF DOOR:

Scavenge belt relief door Fitted to both ends of the scavenge belt and set to lift slightly above the maximum normal working scavenge air pressure.

2. FIRE FIGHTING MEDIA

Carbon dioxide- will put out a fire but supply is limited. Susceptible to loss if dampers do not effective prevent air flow

Water spray- perhaps the ideal solution giving quick effective cooling effect to the fire.

Dry powder- will cover the burning carbon and oil but is messy. As the fire may still smoulder below the powder care must be taken when the scavenge doors are removed as the powder layer may be blown away.

Steam smothering-plentiful and effective

Source: www.marinediesels.info

PREVENTION

Good maintenance and correct adjustment must be carried out

Scavenge trunking must be periodically inspected and cleaned and any buildup of contamination noted and remedied.

The drain pockets should also be cleaned regularly to remove the thicker carbonized oil sludges which do not drain down so easily and which are a common cause of choked drain pipes

Scavenge drains should be blown regularly and any passage of oil from them noted.

The piston rings must be properly maintained and lubricated adequately so that ring blow-by is prevented.

At the same time one must guard against excess cylinder oil usage.

With timed cylinder oil injection the timing should be periodically checked.

Scavenge ports must be kept cleared

The piston-rod packing rings and scraper rings should also be regularly adjusted so that oil is prevented from entering the scavenge space because of butted ring segments.

This may and does occur irrespective of the positive pressure difference between the scavenge trunk and the crankcase space.

Fuel injection equipment must be kept in good condition, timed correctly, and the mean indicated pressure in each cylinder must also be carefully balanced so that individual cylinders are not overloaded.

If cylinder liner wear is up to maximum limits the possibility of scavenge fires will not be materially reduced until the liners are renewed

REFERENCES:

1. www.marineengineering.co.uk

2. The Running and Maintenance of Marine Machinery – Cowley

3. Reeds Marine Engineering Series, Vol. 12 – Motor Engineering Knowledge for Marine Engineers

4. Lamb’s Question and Answers on Marine Diesel Engines – S. Christensen

5. Diesel Engines – A J Wharton

6. www.marinediesels.info

LATEST DEVELOPMENT ON EU-MRV

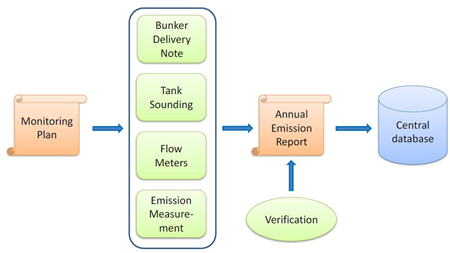

Monitoring Reporting & Verification (MRV) is a standardised method to produce an accurate CO2 emissions inventory, through the quantification of CO2 emissions. The key principles of the scheme are to generate robust results using a lean approach considering parameters which are already monitored during normal operations.

It is advocated as a way of monitoring a ship’s fuel consumption and its operational energy efficiency performance.

MRV is still under discussion in IMO and they will come up with a decision in next MEPC. The new EU Regulation 2015/757 came into force on 1 July 2015 and operating from 2018.

There is a MEPC Working Group active on the subject:

A corresponding working group and pilot testing of various schemes are encouraged.

Work has significantly progressed and is likely to finalise in 2016.

IMO MRV main elements:

Data collection

Data verification

Data submission to a central database.

IMO MRV status:

- Applicable to ships >5000 GT

- Annual reporting

- IMO number for ship identification

- Guidelines will be developed to deal with various aspects.

- Registered owner is responsible for submission of data to Administration

- Administration responsible for verification (can be delegated to ROs).

- A Statement of Compliance will be issued to ship annually

- PSC will examine SFC for enforcement

- Responsibility of reporting remains with ship

- Transport work and other data to be decided later.

The Regulation follows the European Parliament’s Resolution of 5th February 2014, which called upon the Commission and Member States to set a binding target of reducing domestic greenhouse gas emissions by at least 40% compared with levels observed in 1990.

CO2 emissions from international shipping, related to the EU alone, increased by 48% between 1990 and 2007. However, as yet international maritime shipping remains the only means of transportation which has not been included in Community proposals to reduce greenhouse gas emissions.

In light of the developing scientific understanding of the impact of maritime transport on the global climate, it has been decided that this should be assessed regularly and that the European Commission should consider implementing policies and measures to reduce both CO2 emissions and other kinds of emissions from vessels in future. According to data provided by the IMO, the energy consumption and emissions of ships could be reduced by up to 75% by applying operational measures and implementing technologies which already exist. It is believed that the best option for reducing CO2 emissions from shipping is to set up a system for monitoring, reporting and verification (MRV) of CO2 emissions based on the fuel consumption of ships. The MRV system is set out in the form of a Regulation due to the complex and highly technical nature of the provisions introduced, the need for uniform rules applicable throughout the European Union, and to facilitate implementation of these proposals throughout the European Union.

Regulations for MRV

1. Article 4: Article 4 of the Regulation sets out ‘common principles’ for monitoring and reporting. For each ship with a gross tonnage above 5000GT, ship owners must provide a complete report covering CO2 emissions from the combustion of fuels whilst ships are at sea as well as at berth. It is important to apply appropriate measures to prevent any gaps in the data – the whole period must be covered (Article 4(2)).

The data produced must also be accurate – the burden is on the ship owner to identify the source of any inaccuracies and prevent them (Article 4(5)).

Monitoring and reporting must also be consistent. The same monitoring methods and data sets should be used so that the data acquired can be compared overtime and any increase or decrease in emissions can be accurately monitored (Article 4(3)).

The monitoring data itself must be collected and documented in a transparent manner. This will enable any independent verifier to reproduce the methods used to determine the vessel’s CO2 emissions (Article 4(4)).

2. Article 5: Article 5 of the Regulation sets out specific methods for monitoring and reporting vessel emissions, as well as other relevant information, by reference to Annexes I and II. By Article 5(1) any of the methods set out in the Annexes may be used to determine CO2 emissions and other relevant information.

Methods for determining CO2 Emissions

It is recommended that Members look into the detailed provisions of Annexes I and II themselves. However, we include a brief summary of the key points below. Four methods for determining CO2 emissions are given in the Regulation, as set out in the following formulae: (from Annex I):

Fuel consumption x emission factor

For the emission factor, default values shall be used unless the company decides to use the fuel quality data set out in the bunker delivery note for that fuel.

For the actual consumption of fuel, Annex I provides the following approved methods:

Fig: EU-MRV scheme overview (Source: LR)

Method A: Bunker Delivery Notes and Periodic Stock-Takes of Fuel Tanks

This method is based on the quantity and type of fuel as defined in the bunker delivery notes, compared with information gained from periodic stock-takes. The fuel at the beginning of the monitoring period, plus deliveries, minus fuel available at the end of the period and de-bunkered fuel will indicate how much fuel has been consumed.

Fuel tank readings must be carried out by methods such as automated systems, soundings and dip tapes. Whichever method is used, it must be specified in the monitoring plan.

Method B: Bunker Fuel Tank Monitoring On-Board

This method is based on fuel tank readings for all the fuel tanks on board. The readings must take place daily when the ship is at sea and each time the ship is bunkering or de-bunkering. The cumulative variations of the fuel tank level between two readings will constitute the fuel consumed over the period, which might be the time between two port calls or time spent within a port.

As above, the method of taking fuel tank readings must be an ‘appropriate method’ and be specified in the monitoring plan.

Method C: Flow Meters for Applicable Combustion Processes

This method is based on measured fuel flows on board. The data from all the flow meters linked to relevant emission sources will be combined to determine all fuel consumption for a specific period. Again, the period might be the time between two port calls or time spent within a port.

Method D: Direct Emissions Measurement

This method may be used for voyages within the scope of the Regulation and emissions occurring in ports located in a Member State’s jurisdiction. For ships on which reporting is based on this method, fuel consumption will be calculated using measured CO2 emissions and the applicable emission factor of the relevant fuels.

This method is based on the determination of CO2 emission flows in exhaust gas stacks (funnels) by multiplying the CO2 concentration of exhaust gas by the exhaust gas flow.

Monitoring Plan

Under Article 6(1), by 31st August 2017 a monitoring plan must be submitted to the verifiers which indicates the method chosen to monitor and report emissions and other relevant information. Each ‘company’ must submit a separate plan for each ship to which the Regulation applies. Should ships fall within this Regulation only after the 31st August 2017, the plan must be submitted without undue delay (Article 6(2)).

The monitoring plan is meant to be a complete, transparent documentation of the monitoring methodology for the specific ship. It must contain:

a) the identification and type of ship (including its name, IMO number, port of registry and owners’ name);

b) contact details for the ‘company’ responsible for monitoring and reporting;

c) a description of the emission sources on board (the main engines, auxiliary engines, gas turbines, boilers, inert gas generators) and the fuel types used;

d) a description of procedures, systems and responsibilities used to update the list of emission sources;

e) a description of procedures used to monitor the completeness of the list of voyages;

f) a description of the procedures for monitoring fuel consumption, emission factors for each fuel type used (including how these were calculated in the case of alternative fuels);

g) a description of the procedures used to determine activity data per voyage, a description of the method to be used to determine surrogate data (in the case of data gaps); and

h) a revision record sheet to show any revisions which have been made.

As can be seen from the above this is a comprehensive document and therefore templates will be provided in order to streamline and standardise this process. The form these will take is as yet undecided, but it is indicated by Article 6(4) that these will be determined by means of implementing acts in the near future.

Under Article 7, the company is required to modify the monitoring plan in certain situations:

a) if there is a change of company (i.e. another party takes on that role in relation to the vessel);

b) if there are new emission sources or fuels are used which are not yet referred to in the monitoring plan;

c) where there is a change in the availability of data (e.g. because new methods are being used to collect it);

d) where data resulting from previously used methods has been found to be incorrect; or

e) if the monitoring plan does not conform to the above requirements. (If the monitoring plan does not conform, the verifier will request that the company modifies the plan. In other circumstances, the company must notify any planned modifications to the verifiers without undue delay.)

Having chosen a method and prepared a monitoring plan, companies must then monitor emissions for each ship both on a per-voyage & annual basis (Article 8). Where emissions are monitored on a per-voyage basis, Article 9 stipulates that the following information must be monitored:

a) the ports of departure and arrival (including date and time of departure/arrival);

b) the total amount and emission factor for each type of fuel consumed;

c) CO2 emitted;

d) distance travelled;

e) time spent at sea;

f) cargo carried; and

g) transport work.

However, ships are exempted from the need to monitor emissions on a per-voyage basis if all the ship’s voyages either start or end at a port under the jurisdiction of a Member State or the shipper forms more than 300 voyages in a year.

Where emissions are monitored on an annual basis, for each ship the company must monitor:

a) the amount and emission factor for each type of fuel consumed in total;

b) the total aggregated CO2 emitted;

c) the aggregated CO2 emissions from all voyages:

– between ports under a Member State’s jurisdiction,

– which departed from ports under a Member State’s jurisdiction,

– to ports under a Member State’s jurisdiction, and

d) any CO2 emissions which occurred at berth within ports under a Member State’s jurisdiction.

e) In addition, the total distance travelled, total time spent at sea, total transport work and average energy efficiency of the vessel must be monitored.

The schedule for implementation for EU-MRV

Reporting periods are defined as a calendar year. For voyages starting and ending in two different calendar years, the monitoring and reporting data is to be accounted under the first calendar year.

To simplify the preparation of monitoring plans and reporting requirements, electronic templates will be provided by the European Commission (EC). The following timescales have been set as part of the regulation:

Preparation and adoption of supporting technical legislation in 2015/2016 including broad stakeholder and expert involvement

– Accreditation of verifiers in 2017

– 31st August 2017 – Monitoring plan to be prepared and submitted for approval by an accredited verifier

– 1st January 2018 – Commence per-voyage and annual monitoring

– 2019 onwards – By 30th April each year, submit a verified emission report to the EC and relevant flag state

– 30th June 2019 onwards – Ships will need to carry a valid document of compliance relating to the relevant reporting period.

– 30th June each year – the EC will make each ship’s emissions reports publicly available including information specific to that ship, its fuel consumption, CO2 emissions, technical efficiency (EEDI or EIV as appropriate) along with other parameters.

Source: The Japan P&I Club and Lloyd’s Register

CYLINDER LUBRICATION SYSTEM

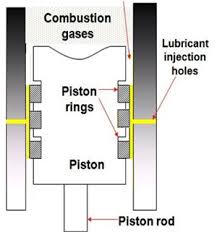

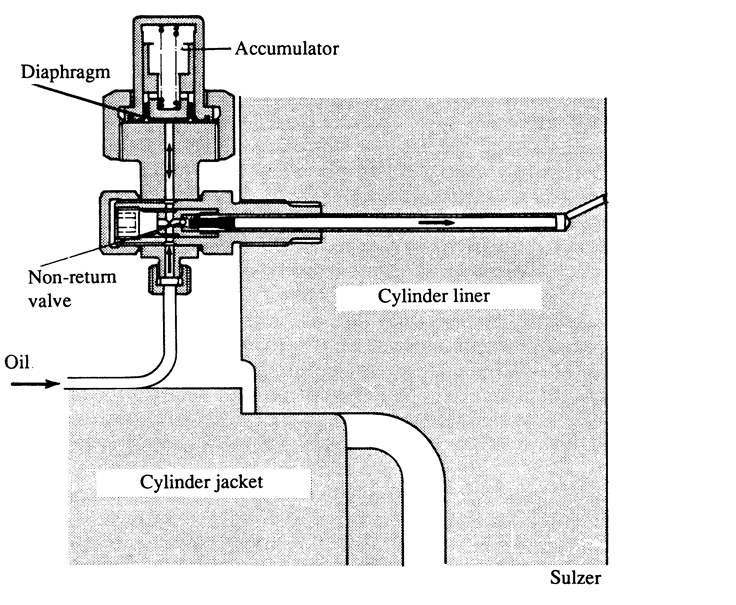

Cylinder lubrication in a low-speed main propulsion diesel engine:

Cylinder lubrication For marine diesel engines operating on residual fuels containing sulphur, cylinder lubrication must generally serve the following purposes:

■ Create and maintain an oil film to prevent metal to metal contact between the cylinder liner and piston rings.

■ Neutralise sulphuric acid in order to control corrosion.

■ Clean the cylinder liner, and particularly the piston ring pack, to prevent malfunction and damage caused by combustion and neutralisation residues.

Cylinder lubricating oil for a low-speed main propulsion diesel engine is admitted to each cylinder during the compression stroke. Cylinder lubricating oil, for lubricating the piston rings and the liner, has to be admitted when the piston, piston rings and the liner are in cool condition and the piston is moving upward so that oil can be retained on the piston rings and sprayed by the piston rings on the liner walls. This is only possible during the compression stroke. Otherwise, the piston is hot and if the lubricating oil is sprayed on it, it will evaporate very fast and will not carry out any work of lubrication. At the same time, if lubricating oil is injected during the expansion stroke, i.e. when the piston is moving downwards, it will have a scrapping effect rather than lubrication.

Cylinder Lubrication in four-stroke trunk piston engine:

In four-stroke trunk piston engines, there are a number of different methods for lubricating the cylinder liners and piston rings, depending on engine size and make:

■ Splash from the revolving crankshaft

■ “Inner lubrication”, where the oil is supplied from the piston side

■ “Outer lubrication”, where the oil is supplied by an external, separate cylinder lubricating device from the cylinder liner side.

In a four-stroke trunk piston engine, the cylinder lubricating oil is identical to the engine system oil used for bearing lubrication and cooling purposes.

A small amount of the cylinder lubricating oil by-passes the piston rings and ends up in the combustion space,

where it is “consumed”. However, the piston in a four-stroke trunk piston engine has an oil scraper ring that scrapes most of the oil supplied to the cylinder liner back to the engine’s oil pan, from where it is drained, cleaned and recycled.

Normally, a large, modern, well maintained four-stroke trunk piston diesel

engine will consume some 0.3 to 0.5 g/kWh of lubricating oil.

Type of Oil Used in Cylinder Lubricating System

- The cylinder lubricant must be of a higher viscosity so that it can form a good lubricating film between the liner and the piston rings.

- It must also withstand the heat variations in the combustion area and must deal with the combustion products.

- Under normal running conditions this oil will typically be an alkaline cylinder lubricating oil of SAE 50 viscosity.

- The alkalinity is indicated by the TBN (Total Base Number ) rating of the lubricant. The TBN value most suitable for the cylinder lubricating oil depends largely on the sulphur content of the fuel used. Typical values for sulphur content of 0.5 to 1% may be between 20 to 25 TBN. For sulphur content over 1.5% the TBN number may be 70 or higher.

Using the Correct Feed Rate for Cylinder Lubrication

Once the correct lubricating oil is chosen the correct feed rate must be established in accordance with the engine builder’s recommendations.

- The feed rate has a critical effect on good engine operation apart from the question of oil consumption. With a too low feed rate the danger of the oil film breaking down causing blow by or additional wear is increased.

- Too high a feed rate is a waste of lubricant and money. The correct feed rate will allow the formation of the lubricating film between the liner and the rings and will give maximum protection at the piston reversal points.

The cylinder oil consumption burette is a useful means of checking the oil consumption of individual lubricator boxes to help ensure that the oil is distributed across the boxes as intended.

The volume between the two internal discs is 1/2 litres. Given the temperature density characteristics of the oil, the actual mass of the oil during

its use in engine calibration can be calculated from the oil temperature. Calibration time lies typically between 3 10 minutes depending on the oil consumption rates and the speed/power of the engine, (if the oil feed drive is speed/power dependent).

In slow speed operation, the use of heavy fuel oil with high sulphur content makes the job of the cylinder lubricant very difficult. Even high alkalinity oils cannot hope to neutralise all the sulphuric acids which are produced during combustion.

Effect of Under Lubrication and Over Lubrication of Cylinder:

A correct viscosity is important in order to ensure the spreadability of the cylinder oil, and the applied feed rate and injected amount of oil per stroke are key factors in the delicate balance between under- lubrication and over- lubrication:

■ Under-lubrication

If too little cylinder oil is supplied, starvation will occur which might result in corrosion, accumulated contamination from unburned fuel and combustion residues, and in the worst case, metal to metal contact, known as “scuffing”.

■ Over-lubrication

If too much cylinder oil is supplied, the loss of fresh, unused oil in the scavenge ports

will be high, and the piston rings might be prevented from moving (rotating) in their grooves by the so called

“hydraulic lock”. Furthermore, the cylinder liner running surface structure might over time become closed and smooth like a mirror, and will no longer be able to retain the lubricating oil. This is sometimes called “chemical bore polish”, and when alkaline deposit build-up on the piston top land from excessive cylinder oil is in contact with the cylinder liner running surface, it can cause what is sometimes called “mechanical bore polish”. All of these phenomena might eventually result in scuffing.

Acid Condensation in the combustion chamber

The cooling system must be operated so that the piston and cylinder liner temperature is not dropped below the temperature at which the Sulphuric acid may condense on the cylinder liner.

Acid condensation depends on:

• the engine combustion pressure

• the liner temperature

• the concentration of the sulphur oxides

• the humidity of the intake air.

So, to help the lubricant in neutralising the acid, the engineer must ensure that the temperature of the scavenge air should be maintained in accordance with the manufacturers’ recommendation. Too low a scavenge air temperature will result in condensation with the risk of moisture entering the cylinders; too high a scavenge air temperature will adversely affect the combustion characteristics of the engine.

Engine Runing-in

Critical to this lubrication area is the way the engine has been run in at commissioning. A good run in procedure will create a good wear in of the cylinder liner and piston ring. A good gas seal is obtained between them whereby a thin oil film provides reliable and effective lubrication.

The period and method of running in should be decided upon in accordance with the engine manufacturer’s recommendation. Even if only new rings have been fitted the running in procedures should be as near as possible to that recommended for new engines.

The running in recommendation may specify the use of a particular type of lubricant and the feed rate should be high. After running in, the normal cylinder oil will be used and the feed rate gradually adjusted until the recommended feed rate is reached.

So, the cylinder lubricating oil must create a lubricating film between the piston ring and the liner, and must maintain effective lubrication. It must also combat corrosive wear. The use of the correct lubricant and the correct feed rate for the engine load will help to achieve the best result from the lubricant.

Lubrication Of Medium Speed Trunk Piston Engine

In medium speed diesel the cylinder is open to the crank case. This means that contamination of the crank case oil by combustion products requires the oil to be different in character to that which may be used in a slow speed engine. Generally, the lubricant must:

* create and maintain effective lubrication between moving components under high mechanical and thermal loads;

* transport solid contaminants from the cylinder to the cleaning devices, such as filters and centrifuges;

* withstand heat; fight contamination, corrosion and wear; resist oxidation and thermal breakdown; keep the engine clean.

References:

1. www.marinediesels.info

2. The Running and Maintenance of Marine Machinery – Cowley

3. Reeds Marine Engineering Series, Vol. 12 – Motor Engineering Knowledge for Marine Engineers

4. Lamb’s Question and Answers on Marine Diesel Engines – S. Christensen

5. Principles and Practice of Marine Diesel Engines – Sanyal

6. www.wartsila.com

THE TRIPLE E SHIP’S CONCEPT FOR MORE ENERGY EFFICIENCY

The Triple E Ships can be more energy efficient and more environment friendly. Triple-E (EEE) stands for Energy efficient, Economy of scale and Environmentally improved vessel:

Energy Efficiency:

Triple-E ships are designed and optimised for lower speeds. The unique hull design, energy-efficient engine and system that uses exhaust gas to produce extra energy to help propel the ship, make the Triple-E unmatched in energy efficiency.

Economy of Scale:

The Triple-E ships break the world record in container ship capacity without requiring more engine power. This design takes economy of scale to a new level.

Environmentally Improved:

The Triple- E ships, with their unique design features for slower speeds and maximum efficiency, emit 50% less CO2 per container moved. (as claimed by Mearsk Line Triple-E project).

Grams of emitted CO2 transporting 1 ton of cargo 1 km:

Triple-E Container Ship: 3g

Conventional railway: 18g

Truck or Lorry on road: 47g

Aeroplane or by air: 560g

Source: www.maersk.com

The Triple E Container Ships:

The vessels will be the most energy efficient. They will have the lowest carbon dioxide (CO2) footprint by emitting 50% less CO2 per container moved when compared to the most efficient container vessel available currently. Optimised design will allow the vessel to cruise with the maximum possible load at speeds prevailing in the industry.

The waste heat recovery system will capture the exhaust gas from the engine and use it to run the turbine to produce mechanical energy, which in turn, will be used to run a generator. It will trim down fuel consumption and CO2 emission by about 9%.

Source: www.maersk.com

Propulsion System:

The Triple-E class vessel will have a twin skeg propulsion system, with two slow running ultra-long stroke engines. Each engine will drive a separate propeller. Each engine will produce 43,000hp and weigh 910t with a specific fuel oil consumption (SFOC) will 168g/kWh. Each of the two propellers will be of 9.8m diameter and have four blades. The smaller the number of blades, the less the resistance will be, while the larger diameter propellers will produce more pushing power. The two engines and two propellers combination will generate further savings of 4% energy when compared to a combination of one engine and one propeller.

Moreover, the triple-E ship’s will be fitted with two Shaft Generator Motors with a rated capacity of 3MW each. The motors will act as variable power generation units which will save more energy.

References:

1. www.maersk.com

2. www.ship-technology.com