Author: Md Taifur Rahman, MEO-2, MPA, 46/E, BMA.

Dual fuel engines were introduced in the marine industry through the gas carriers. But now a day’s large size containers are also started to uses duel fuel engines. These engines use both natural gas and bunker fuel to meet the IMO and MARPOL regulations as its having cleaner-burning properties. Rapidly this engine is getting very popular in the maritime industry due to its higher cost benefits.

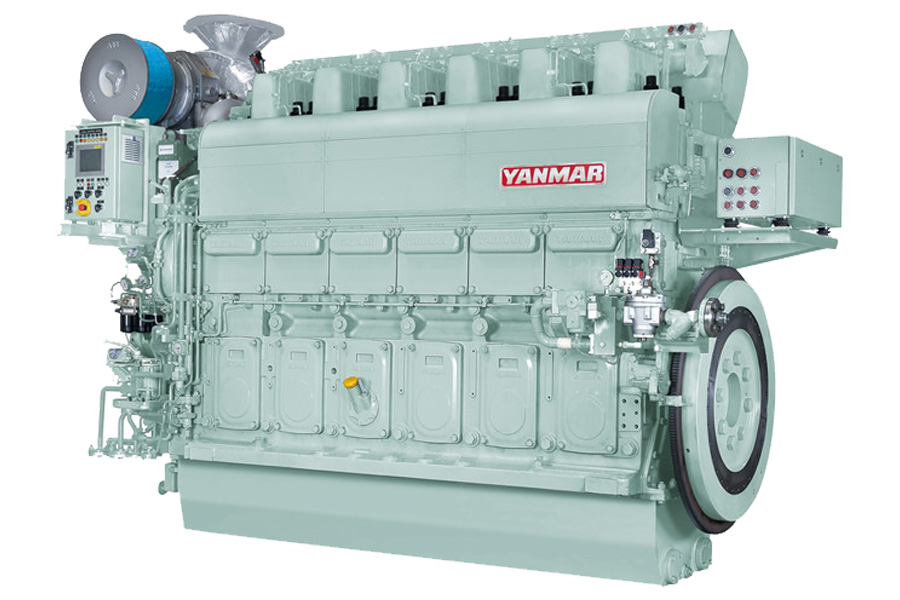

Dual Fuel Engine

Duel fuel engine works on compression ignition principle same like other marine engines. But here two types of fuel are used at the same time. Low-pressure natural gas is supplied to engine cylinder which gets mixed up with air and gets compressed as the piston reaches TDC. But this gaseous mixture of natural gas and air are not good at compression ignition. So small amount of diesel as a pilot fuel is injected to the cylinder to start the combustion process. The sudden injection of diesel can create a knocking problem which is controlled by the quantity of diesel being injected. In some engines, natural gas is compressed up to very high pressure (250-300 bars) before being supplied to the cylinder and then inject at the same time with pilot fuel. This is more efficient than providing gas to the cylinder earlier.

The amount of pilot fuel being injected is around 6% of the total load. But if natural gas supply becomes limited the amount of pilot fuel injection will vary to meet the changing engine load demand. If the natural gas supply is not available the engine will run on “fuel oil mode” only. This mode is used mostly on restricted water, heavy weather, maneuvering, etc.

Some leading duel fuel engine manufactures are caterpillar, MAN Diesel & Turbo, Wartsila, Hyundai, Rolls Royce, Yanmar, Cummins, ABC Diesel.

Some Safety features:

• Engine will continue to run on oil if natural gas is unavailable.

• Engine will use fuel oil during starting

• Run on Fuel oil mode in restricted water, heavy weather, maneuvering etc.

• Crankcase pressure relief valve fitted at both sides of the engine.

• Flame arrester at the air starting line of each unit

• Each unit gas supply valve to be equipped with a flame arrester.

• Independent Exhaust system

Advantages:

• Cleaner exhaust, environmentally sound.

• Less fuel is needed and natural gas is comparatively cheaper.

• Spark plug is not required.

• Engine can run on both gas and fuel oil.

• More efficient than diesel engine at higher load conditions.

Disadvantages:

• Fuel management measures are costly.

• Chances of gas leakage.

• Natural gas bunkering may not be available at all the ports.